-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Civil Engineering Research

p-ISSN: 2163-2316 e-ISSN: 2163-2340

2014; 4(3A): 48-53

doi:10.5923/c.jce.201402.07

Solidification Potential of Fine-Grained Dredged Marine Soils: Water-Binder Ratio Effects

Amira Azhar1, Chee-Ming Chan2, Ahmad Tarmizi AbdKarim1

1Faculty of Civil and Environmental Engineering, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia

2Faculty of Engineering Technology, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia

Correspondence to: Chee-Ming Chan, Faculty of Engineering Technology, Universiti Tun Hussein Onn Malaysia (UTHM), Malaysia.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Dredging activities are important to ensure safe navigation of ships and vessels at ports, harbors, and navigational channels. Dredged marine soils (DMS) is a valuable resource even though not commonly practice. The use of dredged material has a major contribution to make to sustainable development and can reduce the quantities of primary resource needed for activities such as construction and habitat creation. Solidification is a method that aims to improve the engineering properties of soil such as soil strength. Soil stabilization involves the use of stabilizing agents or binder materials in soft soils to improve its geotechnical properties such as compressibility, strength, permeability and durability. The fine-grained DMS sample collected from Marina, Melaka was used in this study. According to Unified Soil Classification System (USCS), the DMS was classified as high plasticity clay (CH). The amount of DMS that will be mixed with the binders was calculated based on water-binders (water-cement) ratio. Calculation for the amount of binders (OPC and BA) for each mixture was calculated from mass of dry sample and moisture content of the sample. The water binder ratios of the samples are 1, 3 and 5.Unconfined compressive strength tests were performed to determine stability of the solidified samples to withstand overburden loads and to determine the increment of strength. The water-binder ratio gives high impact on the increment of the DMS strength. As the water-binder ratio decrease, the DMS strength will increase. Curing days also give effects to strength of the samples. The result shows that strength increase with respect to time.

Keywords: Dredged marine soils, Solidification, Water-binder ratio

Cite this paper: Amira Azhar, Chee-Ming Chan, Ahmad Tarmizi AbdKarim, Solidification Potential of Fine-Grained Dredged Marine Soils: Water-Binder Ratio Effects, Journal of Civil Engineering Research, Vol. 4 No. 3A, 2014, pp. 48-53. doi: 10.5923/c.jce.201402.07.

Article Outline

1. Introduction

- Dredging activities are important to ensure safe navigation of ships and vessels at ports, harbors, and navigational channels. Dredging activities generates large volumes of dredged marine soils (DMS). DMS consist of clean gravel and sands or contaminated fine-grained soils. The fine-grained soils may pose high risks to human health and the environment [1, 2]. Contaminants in DMS can be stabilized or removed by treatment techniques to make it suitable for reuse [3]. Dredged marine soils are a valuable resource even though not commonly practice. The use of dredged material has a major contribution to make to sustainable development and can reduce the quantities of primary resource needed for activities such as construction and habitat creation. Some countries do already make extensive use of dredged material, for example in Japan in 2003 more than 90% of dredged material was used [4].Solidification is a method that aims to improve the engineering properties of soil such as soil strength. There are two types of stabilization that are commonly used nowadays that are mechanical stabilization and chemical stabilization. Soil stabilization involves the use of stabilizing agents or binder materials in soft soils to improve its geotechnical properties such as compressibility, strength, permeability and durability. The components of stabilization technology include soils and binders. The binders used normally are cementitious materials [5]. The factors that affect the physical properties of mixing of soil-cement are including the soil type, quantity of cement, degree of mixing, curing time and dry density of the compacted mixture [6]. Solidification binders are materials that form cementitious composite materials when in contact with water or in the presence of pozzolanic minerals that reacts with water. The material used for cementitious material is also known as binder. The commonly used binders are cement, lime and fly ash [5]. Ordinary portland cement (OPC) is a mechanical additive that can be used for soil solidification. OPC is a common type of fine powdery cementitious building material. When mixed with water and sand (or gravel), it turns into masonry mortar (or concrete). After a series of complex internal reactions (hydration), the mixing would sets like a stone.Bottom ash is produced as a result of burning coal in a dry bottom pulverized coal boiler. It consists of non-combustion materials. Raw bottom ash is a granular material that consists of a mix sand, stone, glass, porcelain, metals, and ash from burnt materials. The non-combustion material from a dry bottom boiler consists of 20 % of bottom ash. Generally, bottom ash is a porous, glassy and dark gray material with a grain size similar to that of sand or gravelly sand.Successful modern soil stabilization techniques are necessary to assure adequate subgrade stability, especially for weaker soils [7]. The increase of cement content and curing time caused significant improvement of unconfined compressive strength as well as stiffness of the treated clay [8]. There are many advantages of soil stabilization such as improved the strength of soil and helped to reduce soil volume changes due to temperature or moisture. A part from that, soil stabilization also can improve the soil workability, improves durability of soils, reduce the cost and conserve the energy. Stabilization also can reduce the need for borrowing pit materials. It also can reduce the need for landfill site for dumping poor materials [9]. Abram’s law state that the strength development in concrete technology depends on water-to-cement-ratio [10]. Water-cement (water-binder) ratio of soil was used by taking considered on this law and characteristic of soil and cement [11]. The water–binder ratio is the ratio of weight of water to the weight of binder used in a soil mix. The water-binder ratio has an important influence on the quality of soil mixing that was produced. A lower water-binder ratio will leads to higher strength and durability. Soil-binder ratio is a compacted mixture of pulverized soil, portland cement and water. As the cement hydrated it will forms a hard, durable and low cost paving materials. Soil-cement will undergo chemical reaction between cement and water just like concrete mixture. Water must be available during this chemical reaction in order for soil-cement to gain strength [12].

2. Materials and Methods

2.1. Materials

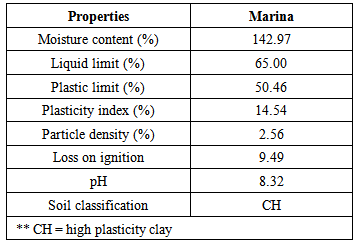

- The fine-granined dredged marine soils (DMS) sample for this study was collected from Marina (Melaka). Most of the dredging activities in Malaysian ports are managed by Marine Department of Malaysia including Marina, Melaka. DMS was collected by backhoe dredger at a depth of 3.5-6.5m from sea level. The amount of DMS collected at Marina, Melaka is about 120,000 m3. The samples collected were put in sealed plastics bag to avoid moisture loss during transportation. Samples were stored indoors to avoid direct sunlight and heat. Figure 1 show typical picture of dredged marine sediments.

| Figure 1. Typical picture of dredged marine sediments |

|

|

2.2. Methods

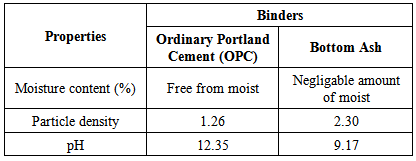

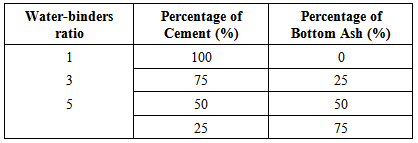

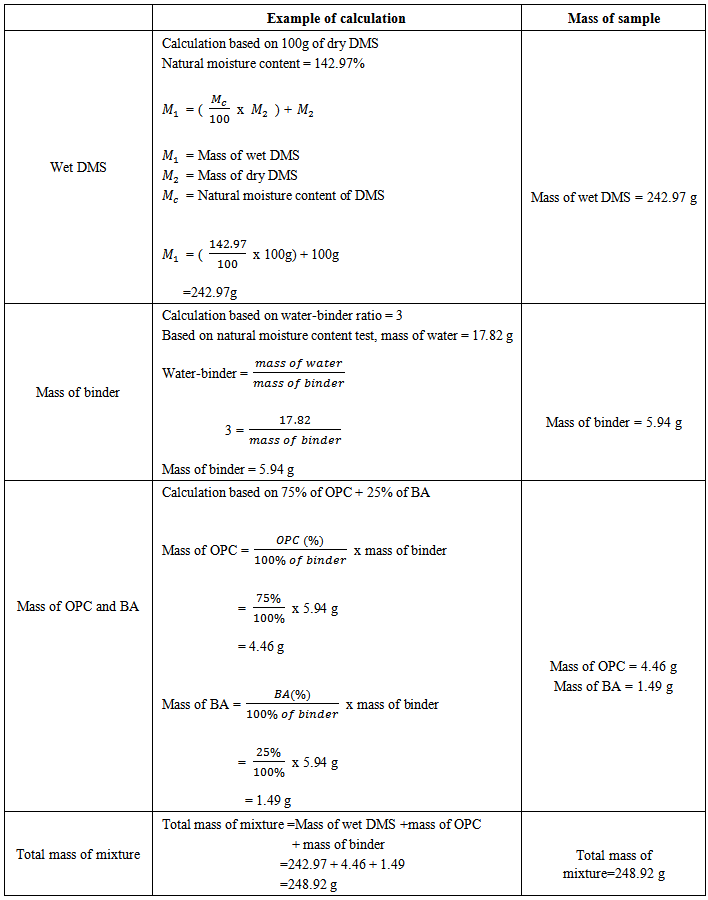

- The mixing of fined-grained dredged marine soils (DMS) was conducted based on water-binder ratio (ww/wb) which was adapted from water-cement ratio that was used concrete technology. The first step to determine the water-binder ratio is to obtain the natural water content of the sample. Natural water content of DMS is 142.97%. The amount of wet DMS can be obtained based on the dry weight of DMS. The water-binder used in this study was 1, 3 and 5. Based on the water-binder ratio that had been set up, the calculation of the amount of ordinary Portland cement and bottom ash can be obtained. Table 3 show the percentage of binder used in this study. Table 4 show the calculation of DMS mixture with binder based on the water-binder ratio.

|

|

3. Result and Discussion

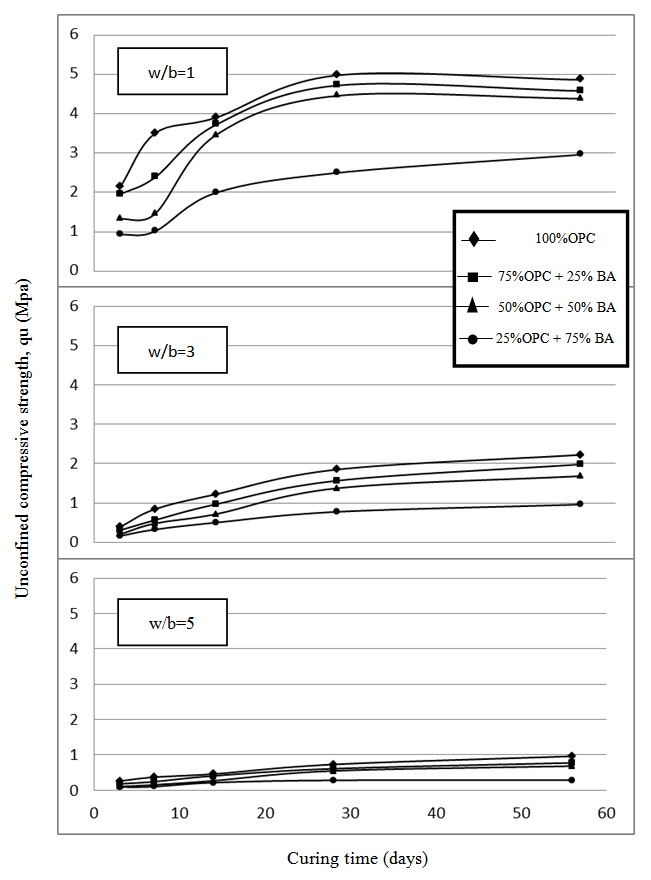

- Without any solidification process or treatment, the natural dredged marine soils (DMS) has low undrained shear strength. The value of shear strength of natural DMS is 2-4 kPa. The solidification process is needed to improve the properties of DMS. Unconfined compressive strength (UCS) tests were performed to determine the strength of the solidified samples to withstand the overburden load. The degree of reaction between soil-binder mixture and hardening rate can also be determined from unconfined compressive strength test.Figure 2 shows the effect of curing on unconfined compressive strength based on water-binder ratio (w/b). The water-binder ratio affected the increment of the DMS strength. As can be seen in Figure 2, the sample with w/b=1 has the highest strength. For w/b=1 with 100% of OPC, the graph can be seen increase rapidly starting from day 3 and has small increment after day 14 until day 28. The same increment can be seen for sample w/b=1 with 75%OPC + 25% BA and for sample with 50%OPC + 50%BA. At day 56, the strength of solidified DMS decreased. For the 25%OPC + 75%BA, the sample strength increase continuously.

| Figure 2. Effects of curing day effects on unconfined compressive strength |

4. Conclusions

- The water-binder ratio affect on the increment of strength of dredged marine soils (DMS). It was observed that, as the water-binder ratio decrease, the strength increase rapidly. The mixing percentage of the binders also affected in strength improvement of the samples. As the percentage of the cement increased and the percentage of the binder decreased, the strength of solidified samples also increased. Curing days also give effects to strength of the samples. The result shows that strength increase with respect to time. As the age of the sample increases, the different in strength of each sample tends to gets smaller. Generally, it can be observed that, longer period of curing time results in greater strength gain. The improvement of the strength of solidified soils is due to the hardening process of the cement.

ACKNOWLEDGEMENTS

- Special thanks goes to Jabatan Laut Malaysia and Malaysian Maritime & Dredging Corporation Sdn. Bhd (MMDC) for giving us access to the sampling site. Besides that, we also would like to thanks RACE Vot 1115, Science Fund Vot S025 and Geran Insentif Penyelidik Siswazah (GIPS) for financial support.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML