A. Arivumangai1, T. Felixkala2

1Research scholar, Department of Civil Engineering, St. Peter’s University, Chennai, India

2HOD, Department of Civil Engineering, Dr. MGR Educational and Research Institute University, Chennai, India

Correspondence to: A. Arivumangai, Research scholar, Department of Civil Engineering, St. Peter’s University, Chennai, India.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The most commonly used fine aggregate across world is river sand. River sand is expensive due to excessive cost of transportation from natural sources. Also large scale depletion of the source creates environmental problems. As environmental, transportation and other constraints make the availability and use of river sand less attractive. A substitute or replacement product for concrete industry needs to be found. The main parameter investigated in this study is M30 grade concrete with replacement of sand by granite powder by 0, 25 and 50% and cement was partial replacement with silica fume, fly ash, slag and super plasticizer. This paper presents a detailed experimental study on compressive strength, split tensile strength 28, 56 and 90 days. Durability study on chloride attack was also studied and percentage of weight loss is compared with normal concrete. Test results indicate that use of granite powder and admixtures in concrete has improved the performance of concrete in strength as well as in durability aspect.

Keywords:

Granite powder, Strength, Durability properties, Chloride attack, Tensile and compressive strength, Fine aggregate

Cite this paper: A. Arivumangai, T. Felixkala, Strength and Durability Properties of Granite Powder Concrete, Journal of Civil Engineering Research, Vol. 4 No. 2A, 2014, pp. 1-6. doi: 10.5923/c.jce.201401.01.

1. Introduction

High Performance Concrete (HPC) is the recent development in concrete. It has become more popular these days and is being used in many prestigious projects. Mineral admixtures such as fly ash, as, silica fume etc. are more commonly used in the development of HPC mixes. Fine aggregate is an essential component of concrete. The most commonly used fine aggregate is natural river sand. The global consumption of natural river sand is very high due to the extensive use of concrete. In particular, the demand of natural river sand is quite high in developed countries owing to infrastructural growth.The non-availability of sufficient quantity of ordinary river sand for making cement concrete is affecting the growth of construction industry in many parts of the country. Recently, Tamil Nadu government (India) has imposed restrictions on sand removal from the river beds due to unsafe impacts threatening many parts of the state. On the other hand, the granite waste generated by the industry has accumulated over years. Indian granite stone industry currently produces around 17.8 million tons of solid granite waste, out of which 12.2 million tons as rejects at the industrial sites, 5.2 million tons in the form of cuttings / trimmings or undersize materials and 0.4 million tons granite slurry at processing and polishing units. The granite waste generated by the industry has accumulated over years. Only insignificant quantities have been utilized and the rest has been dumped unscrupulously resulting in environment problem.In the present work, it is aimed at developing a new building material from the granite scrap, an industrial waste as a replacement material of fine aggregate in concrete. By doing so, the objective of reduction of cost of construction can be met and it will help to overcome the problem associated with its disposal including the environmental problems of the region. Substitutions of alternate materials can result in changes in the performance characteristics that may be acceptable for high performance concrete. Use of chemical admixtures usually superplasticiser reduces the water content, thereby reducing the porosity within the hydrated cement paste (Bharatkumar et al., 2001). Silica fume, fly ash and blast furnace slag are generally called as mineral admixtures and called as cement replacement materials. These are pozzolanic in character and develop cementing properties in a similar way as normal Portland cement when they come in contact with free lime. Use of these materials individually or in combination with cement and proper dosage of superplasticiser improves the strength and durability of products. The admixtures can be added to cement concrete as a partial replacement of cement along with superplasticiser as a water reducer to get the high performance. It is well recognized that the use of silica fume as a partial replacement for cement provides a significant increase in strength of concrete (Xiaofeng et al., 1992). The addition of silica fume to cement paste has been shown to give rise to high early strengths (Mitchell et al., 1998). Silica fume is used in concrete for increased strength development, reduced permeability and economy (Francis, 1994). Mineral admixtures such as fly ash and slag have the inherent ability to contribute to continued strength development and very high durability, the latter through pore refinement and reduced sorptivity. Moreover, Swamy (1991) showed that of all the mineral admixtures, silica fume is a class apart from fly ash and slag because its mineralogical composition and particle size distribution. The mass of silica fume, when used, represents 5 to 15% of the total mass of the cementitious material, the value of 10% being typical. Moreover, silica fume is very expensive. Wasting a very expensive material is not good engineering practice (Adam & Pierre-Claude, 1998). While considering the inclusion of fly ash and slag in the mix, these materials are generally cheaper than Portland cement. Secondly, they do not contribute to the slump loss. On the other hand, mixes that have more fly ash or more slag develop a lower strength, but this can be compensated by lowering the ratio of the mass of water to the total mass of cementitious material (Adam & Pierre-Claude, 1998). The concrete with 10% fly ash exhibited higher early strength followed by an excellent development of strength over time (Haque & Kayali, 1998). Hence, it is expected that the incorporation of silica fume in concrete with fly ash and slag as a partial replacement of cement could contribute the high strength concrete. Accordingly, this paper will examine the properties of concrete by varying the granite powder as a replacement of sand in the concrete that have originated from granite crushed unites along with admixtures such as silica fume, fly ash, ground granulated blast-furnace slag and superplasticiser as a partial replacement of cement.

1.1. Review of Literature

T. Felixkala (et al. 2010) [1] had obtained the test results that granite powder of marginal quantity as partial sand replacement has beneficial effect on the mechanical properties such as compressive strength, split tensile strength, modulus of elasticity. They also indicated that the values of both plastic and drying shrinkage of concrete in the granite powder concrete specimens were nominal than those of ordinary concrete specimens. They examine the possibility of using granite powder as replacement of sand and partial replacement of cement with fly ash, silica fume, slag and superplasticiser in concrete. The percentage of granite powder added by weight was 0, 25, 50, 75 and 100 as a replacement of sand used in concrete and cement was replaced with 7.5% silica fume, 10% fly ash, 10% slag and 1% superplasticiser. The effects of water ponding temperatures at 26℃ and 38℃ with 0.4 water-to-binder (w/b) ratios on mechanical properties, plastic and drying shrinkage strain of the concrete were studied and compared with natural fine aggregate concrete.Kanmalai Williams. (et al 2008 [2]) reported the results of an experimental study on the high performance concrete made with granite powder as fine aggregate. The percentage of granite powder added by weight a range viz. 0, 25, 50, 75 and 100% as a replacement of sand used in concrete and cement was replaced with 7.5%Silica fume, 10% fly ash, 10% slag and 1% super plastiziser. The effects of curing temperature at 32 Sand 0.40 water-to-binder (w/b) ratio for 1, 7, 14, 28, 56 and 90 days on compressive strength, split tensile strength, modulus of elasticity, drying shrinkage and water penetration of concrete were studied. Their results indicated that the increase in the proportions of granite powder resulted in a decrease in the compressive strength of concrete.The highest compressive strength was achieved in samples containing 25% granite powder concrete, which was 47.35 kPa after 90 days. The overall test performance revealed that granite powder can be utilized as a partial replacement of natural sand in high performance concrete.

1.2. Research Objective

Consequently the main objective of this research is to 1) Investigate the potential use of granite powder in concrete as replacement for natural sand. 2) Determining under what conditions the granite powder, in conjunction with silica fume, Fly-ash, and ground granulated blast furnace slag, and increases the strength of concrete when these are used as partial replacement materials. 3) Determining the degree of strength improvement in concrete obtained with the addition of granite powder and admixtures such as silica fume, Fly-ash, and ground granulated blast-furnace slag. In general high performance concrete will be made with cement, admixtures, aggregates and water. The percentage of granite powder added by weight a range viz. 0, 25 and 50% as a replacement of sand (fine aggregates) used in concrete. Mixes incorporating 0% granite powder, or 25% granite powder, or 25% granite powder were designated as GP0, GP25 and GP50 respectively. Cement was replaced with Silica fume, fly ash, slag and superplasticiser for each concrete mixes. The effects of curing temperature, water-to-binder (w/b) ratio for 28, 56 and 90 days on compressive strength of concrete were studied.M. G. Shaikh (et al 2011) [3] has found that the mixes with the artificial sand with dust as fine aggregate gives consistently higher strength than the mixes with natural sand. The sharp edges of the particles in artificial sand provide better bond with the cement than the rounded part of the natural sand. It was found that the weight loss of artificial sand block is considerably same with respect to natural sand blocks at 20, 40, and 60 and 90 days, immersed in sulphuric acid solution during the experimental period and maintains pH 4 across it. Both concrete made using artificial sand and natural sand are moderate to chloride permeability. In water absorption test we observed after 24 hours curing, the increase in weight of both natural sand and artificial sand blocks are less than 3% that means both concrete are low absorber hence concretes are good quality. The test result obtained from well planned and carefully performed experimental program encourage the full replacement of natural sand by artificial sand with dust considering the technical, environmental and commercial factor.R. Ilangovana et al 2008) [4]. The Durability of Quarry Rock Dust concrete under sulphate and acid action is higher inferior to the Conventional Concrete. Permeability Test results clearly demonstrates that the permeability of Quarry Rock Dust concrete is less compared to that of conventional concrete. The water absorption of Quarry Rock Dust concrete is slightly higher than Conventional Concrete Therefore; the results of this study provide a strong support for the use of Quarry Rock Dust as fine aggregate in Concrete Manufacturing. Thus, it can be concluded that the replacement of natural sand with Quarry Rock Dust, as full replacement in concrete is possible.B. B. Patel (et al 2012) [6] The compressive strength of concrete increases with increase in HRM content up to 7.5%. Thereafter there is slight decline in strength for 10%, 12% and 15% due excess amount of HRM which reduces the w/b ratio and delay pozzolanic activity. The higher strength in case of 7.5% addition is due to sufficient amount of HRM available to react with calcium hydroxide which accelerates hydration of cement and forms C-S-H gel. The 7.5% addition of high reactivity metakaolin in cement is the optimum percentage enhancing the compressive strength at 28 days by 7.73% when compared with the control mix specimen. The 7.5% addition of high reactivity metakaolin in cement is enhanced the resistance to chloride attack. The compressive strength of concrete incorporated with 7.5% HRM is reduced only by 3.85% as compared with the reduction of strength of control mix specimen is by 4.88%. The 7.5% addition of high reactivity metkaolin in cement is also enhanced the resistance to sulphate attack. The compressive strength of concrete incorporated with 7.5% HRM is reduced only by 6.01% as compared with the reduction of strength of control mix specimen by 9.29%.

2. Experimental Details

2.1. Materials

2.1.1. Cement

The materials of cement was used in an ordinary Portland cement super grade IS: 1489 (53grade) is used. This cement is most commonly used in concrete construction.

2.1.2. Fine Aggregate

In current study, the high performance concrete mixes were prepared using locally available river sand. The sand used was confining to zone 3. Fineness modulus and specific gravity of the sand were found to be 2.33 and 2.56 respectively.| Table 1. Properties of Granite |

| | Sl No | Properties | Values | | 1 | Porosity | Very low | | 2 | Absorption | 0.5 to 1.5% | | 3 | Specific Gravity | 2.6 to 2.8 | | 4 | Density | 2500-2650Kg/m3 | | 5 | Crushing strength | 1000-2500Kg/m2 | | 6 | Frost resistance | Good | | 7 | Fire resistance | Low | | 8 | Color | Mostly light colored |

|

|

2.1.3. Coarse Aggregate

Broken granite stones were used as a coarse aggregate in concrete. Size of the coarse aggregate used in the investigation was 10 -20 mm. The specific gravity of the coarse aggregate was found to be 2.68.

2.1.4. Water

Water is an important ingredient of the concrete as it actually participates in the chemical reaction with cement. In general, water fit for drinking is suitable for mixing concrete. Impurities in the water may affect setting time, strength, shrinkage of concrete or promote corrosion of reinforcement. Locally available drinking water was used in the present work.

2.1.5. Granite Powder

Granite belongs to igneous rock family. The density of the granite is between 2.65 to 2.75 g/cm3 and compressive strength will be greater than 200MPa. Granite powder obtained from the polishing units and the properties were found. Since the granite powder was fine, hydrometer analysis was carried out on the powder to determine the particle size distribution. From hydrometer analysis it was found that coefficient of curvature was 1.95 and coefficient of uniformity was 7.82. The specific gravity of granite powder was found to be 2.5.

2.1.6. Admixture

a). Superplasticiser was used during investigation to improve the workability of concrete. As per Indian standards, the dosage of superplasticiser should not exceed 2% by weight of the cement. A higher dosage of superplasticiser may delay the hardening process. After trials, the optimal dosage of the superplasticiser was found to be 0.5% to produce slump of 100 mm.b). Silica fume Condensed silica fume is considered as the most efficient micro filler for high performance concrete. Its two fold effects are reduction of w/c ratio and increase of strength of hardened concrete. The silica fume used in this study was in powder form and contained 95%SiO, 0.39% 2CaO, 0.21%MgO, 0.11%K O, 0.15% Na O, 0.13% Al O,).40% Fe O The 2 2 23 23.properties of silica fume result in more efficient gelc). Fly ash Fly ash was considered in the present study as a replacement of cement in 10%. It is a fine, glass powder recovered from the gases of burning coal during the production of electricity. Fly ash improves considerably the performance of binder phase and increase the bonding action with aggregate and reinforcement. The properties of fly ash may vary considerably according to several factors Such as the geographical origin of the source coal, Conditions during combustion and sampling position within the power plant. The major elemental constituents of fly ash are Si, Al, Fe, Ca, C, Mg, K, Na, S, Ti, P and Mn.| Table 2. Chemical and Physical Properties of Fly Ash and Slag (%) |

| | Sl No | Properties | Values | | 1 | Specific gravity | 1-220-1-225 | | 2 | Chloride content | Nil (As per BS:5075) | | 3 | Recommended dosage | 2-4% of cement | | 4 | Approximate additional air Entrainment | 1% at normal dosage | | 5 | Solid content | 40% | | 6 | Compatibility | All types of cement except high alumina cement | | 7 | Operating | 10-40 |

|

|

d). Slag The ground granulated blast furnace slag was used 10% along with other admixtures as a replacement of cement| Table 3. Magnetic Properties of silica fume |

| | Sl No | PROPERTIES | | 1 | Specific Gravity : 2.25 (Determined Using Le-Chaterlier flask ) | | 2 | Bulk density: 709 kg/m3 | | 3 | Void content (Vv/V): 2.25 | | 4 | Porosity(Vv/V) : 68.49 % |

|

|

2.2. Mixing, Demoulding and Curing

Thorough mixing and adequate curing are most essential for achieving a good concrete. In the laboratory, the concrete was mixed in a hand mixing. The mixing time was kept to about 3–4 min for normal concrete. Generally, the demoulding was done 24 hr of casting. Potable water was used for curing all the concretes. All the concretes were kept in moist environment immediately after the initial set and before the demoulding.

3. Experimental Procedure

3.1. Compressive Strength

The compressive loading tests on concrete were carried out on a compression testing machine (CTM) of capacity 3000 kN. For the compressive strength test, a loading rate of 2.5 kN/s was applied as per IS: 516–1959 [4]. The specimen used was 150 mm cube. The Test was performed at 28, 56 and 90 days. The specimens were tested immediately after taking the cubes from curing tank in surface dry condition.

3.2. Split Tensile Strength

The split tensile strength test was carried out on a universal testing machine (UTM) of capacity 600kN. For the split tensile strength test, a loading rate of 2.5kN/s was applied as per IS: 516–1959 [4]. The specimen used was 150 mm cube. The Test was performed at 28, 56 and 90 days. The specimens were tested immediately after taking the cubes from curing tank in surface dry condition.

3.3. Chloride Attack

The chloride resistance of the concretes was studied through chemical attack by immersing concrete blocks in 5% Nacl solution. After 90 days period of curing, the specimens were removed from the curing tank and their surfaces were cleaned with a soft nylon brush to remove weak reaction products and loose materials from the specimen. The solution was replaced at regular intervals to maintain constant concentration throughout the test period. The mass of specimens were measured at regular intervals up to 90 days, and the mass losses were determined. | Figure 1. Chloride Attack |

| Figure 2. Water Curing |

4. Results and Discussion

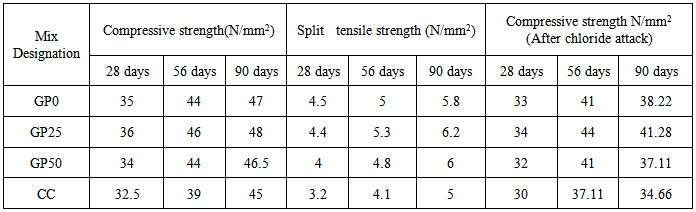

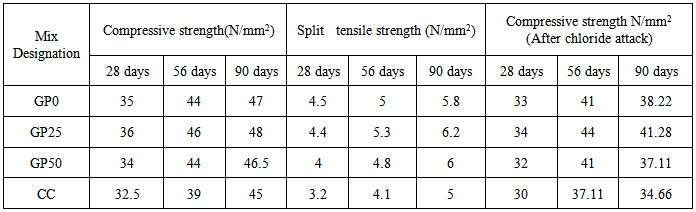

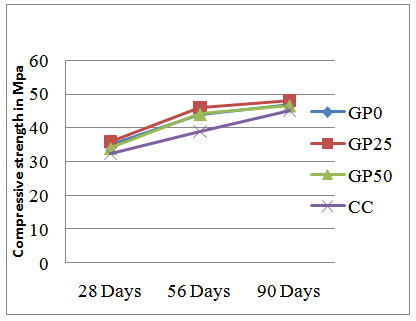

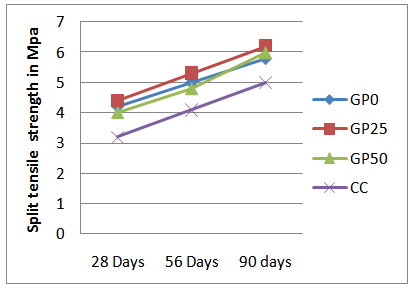

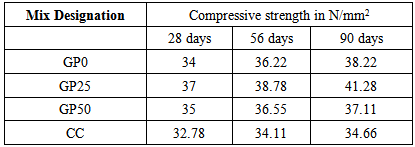

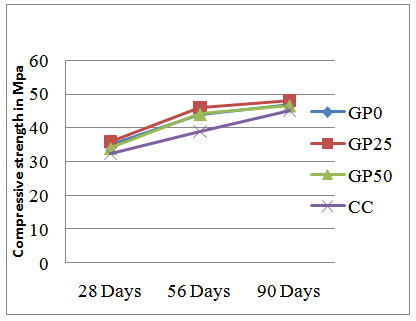

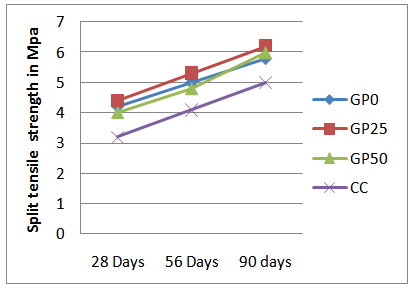

4.1. Compressive Strength and Split Tensile Strength

The compressive strength and split tensile strength of different concrete mixtures at different testing ages is presented in Table 4 and illustrated in Fig. 3 and Fig. 4. The data presented show that the compressive strength of all the granite powder concrete was closer to that of reference mix (GP0) for all the days of curing. The variation of compressive strength and split tensile strength with respect to type of concrete block made by using Conventional Concrete and granite powder concrete are observed. Results shows that the mixes with the granite powder as fine aggregate gives consistently higher strength than the mixes with natural sand. In the present study, significant increase was observed in the concrete mixture with 25% granite powder. The compressive strength of granite powder concrete was increased when admixtures were used. The compressive strength of GP25 is 2 to 9% higher than that of GP0 for all the days of curing. The other mixes with higher than 25% GP showed lesser compressive strength than the mix with the river sand. The split tensile strength of concrete are observed from fig. that the tensile strengths decreased with increase of granite powder in the mix and the results indicate that the optimum replacement is 25%.Table 4. Compressive strength and split tensile strength

|

| |

|

| Figure 3. Variation of compressive strength |

| Figure 4. Variation of split tensile strength |

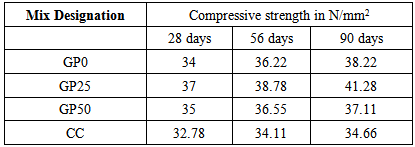

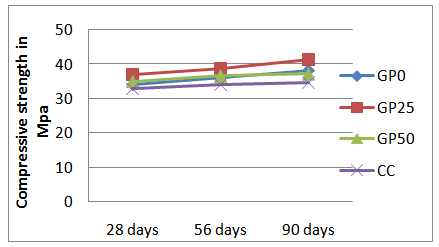

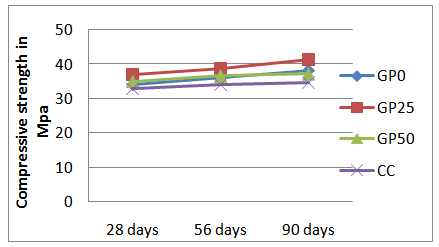

4.2. Chloride Attack

Fig.5 shows that the compressive strength of all the granite powder concrete was closer to that of reference mix (GP0) for all the days of curing. The chloride resistance of the concretes was studied through chemical attack by immersing concrete blocks in 5% Nacl solution. After 90 days pe riod of curing, the specimens were removed from the curing tank and their surfaces were cleaned with a soft nylon brush to remove weak reaction products and loose materials from the specimen. | Figure 5. Variation of compressive strength (after chloride attack) |

The solution was replaced at regular intervals to maintain constant concentration throughout the test period. The mass of specimens were measured at regular intervals up to 90 days, and the mass losses were determined.

5. Conclusions

• The test results show clearly that granite powder as a partial sand replacement has beneficial effects of concrete. Of all the 3 mixtures considered, GP25 was found to be superior to other mixtures as well as GP0 for all operating conditions.• Compressive strength and split tensile strength, particularly in all the ages were higher than that of reference mix. There was an increase in strength as the days of curing increases.• From Table 5 it was concluded that the percentage loss of strength in the chloride test depends upon the replacement of granite powder. • The 25 per cent granite powder concrete enhanced the resistance and thus could improve the chemical resistance of concrete.• The present experimental programme indicated that the strength and durability properties of the concrete could enhance the effect of utilization of granite powder obtained from the crusher units in the place of river sand in concrete.Table 5. Compressive strength in N/mm2 (After chloride attack)

|

| |

|

ACKNOWLEDGEMENTS

The authors would like to thank the management of Dr MGR educational and research Institute University for providing all the facilities for conducting the experimental study in material testing and P.G. laboratory.

References

| [1] | T. Felixkala, P. Partheeban, ‘Granite powder concrete’ Indian Journal of Science and Technology vol.3,No.3(Mar 2010) ISSN: 0974-6846. |

| [2] | Kanmalai Williams C., Partheeban. P, Felixkala. T, ‘Mechanical properties of high-performance concrete incorporating granite powder as fine aggregate’ International Journal on Design and Manufacturing Technologies, vol.2, No.1, July 2008. |

| [3] | M.G. Shaikh, S.A. Daimi ‘Durability studies of concrete made by using artificial sand with dust and natural sand’ International Journal of Earth Sciences and Engineering ISSN 0974 - 5904, vol. 04, No.06 SPL, Oct 2011, p 823-825. |

| [4] | R. Ilangovana, N. Mahendran, Nagamani, ‘Strength and durability properties of concrete containing quarry dust as fine aggregate’, ARPN journal of engg and applied sciences, vol3,No.5, oct2008, ISSN 1819-6608. |

| [5] | H. Binici, M.Y. Durgun, T. Rizaoglu, M. Kolucolakb ‘Investigation of durability properties of concrete pipes incorporating blast furnace slag and ground basaltic pumice as fine aggregates’ Scientia Iranice A (2012) 19(3), 366-372. |

| [6] | J. Prabakar, P. Devadas Manoharan and M. Neelamegam ‘Effect of fly ash on the Durability and performance of concrete’ The Indian concrete journal(Nov 2011). |

| [7] | B. Chatveera , P. Lertwattanaruk, ‘Durability of conventional concrete containing black rice husk ash’ Elsever Journal of Environmental Management 92 (2011) 59-66. |

| [8] | P. Nath, P. Sarker ‘Effect of fly ash on the Durability properties of high strength concrete’ Elsevier Procedia Engineering 14(2011) 1149-1156. |

| [9] | N. Bouzoubaa, M.H. Zhang, and V.M. Malhotra ‘Mechanical properties and durability of concrete made with High-Volume fly ash blended cements using a coarse fly ash’ Elsevier Cement and Concrete Research, vol.31,No.3,Oct 2001, pp.1393-1402. |

| [10] | Fernando Pacheco-torgal- said jalali, ‘Compressive strength and durability properties of ceramic wastes based concrete’, Elsevier Materials and structures (2011) 44:155-167 DOI 10.1617/s11527-010-9616-6. |

| [11] | Adam Neville and Pierre-Claude Aitcin (1998) High performance concrete– an overview. Materials Structures. 111 –117. |

| [12] | Al-Amoudi OSB, Maslehuddin M and Abiola TO (2004) Effect of type and dosage of silica fume on plastic shrinkage in concrete exposed to hot weather. Construction Building Material. 18, 737-743. |

| [13] | Bharatkumar BH, Narayan R, Raghuprasad BK and Ramachandramurthy DS (2001) Mix proportioning of high performance concrete. Cement Concrete Composites.23, 71–80. |

| [14] | Francis A Qluokun (1994) Fly ash concrete mix design and the water-cement ratio law. ACI Material J. 362- 367. |

| [15] | Geetha A and Perumal P ‘Chemical permeability studies on concrete using waterproofing admixture’ journal of structural engineering, vol.38, No.5, (jau2012) pp.495-503. |

| [16] | Haque MN and Kayali O (1998) Properties of high- strength concrete using a fine fly ash. Cement Concrete Res. 1445–1452. |

| [17] | IS: 516 (1959) Methods of tests for strength of concrete. Bureau Ind. Stds. New Delhi, India. |

| [18] | Job T (2005) Utilization of quarry powder as a substitute for the river sand in concrete. J. Structural Engg. 401-407. |

| [19] | Kefeng Tan and Xincheng Pu (1998) Strengthening effects of finely ground fly ash, granulated blast furnace slag, and their combination. Cement Concrete Res. 1819-1825. |

| [20] | Mitchell DRG, Hinczak I and Day RA (1998) Interaction of silica fume with calcium hydroxide solutions and hydrated cement pastes. Cement Concrete Res. 1571-1584. |

| [21] | Swamy (1991) Mineral admixtures for high- strength concrete. Ind. Concrete J 265-271. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML