-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2016; 6(1A): 22-27

doi:10.5923/c.ep.201601.04

Design, Fabrication and Analysis of a Semicircular Solar Water Heater

Vishwanath Nayak1, Venkatesh Rao1, Mallikappa2, Eshwaraih1

1Department of Mechanical Engineering, MMCT, Mangalore, Karnataka, India

2Department of Mechanical Engineering, NMAM Institute of Technology, Nitte, Karnataka, India

Correspondence to: Vishwanath Nayak, Department of Mechanical Engineering, MMCT, Mangalore, Karnataka, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This paper deals with the design and fabrication of a semicircular solar water heater to use renewable energy to obtain hot water. The solar water heater is made by using locally available materials like dripping pipe, coir, plastic drum, G.I. sheet, hose pipes etc. Work has been done on three types of set-ups and investigated for the period of two months. In the performance evaluation, inlet and outlet temperatures of hot water and cold water are measured. Semicircular setup without any insulation and heat absorber plate will not give enough amount of hot water. The same setup with insulation and G.I sheet absorber plate coated with black colour but without transparent cover will also not give sufficient temperature rise to the hot water. But setup with insulation, blackened G.I sheet cover and transparent plastic cover which covers the pipes gives good amount of hot water. The maximum temperature attained in this set-up is 72°C. This hot water is stored in insulated drum of 150 litre capacity and that preserves water as hot for the period of 12-15 hours. The water flow takes place due to thermo siphon effect. Total cost of this project is INR 7500. Since this work is a ongoing project, the final set-up- which is more efficient, should be studied further for other two seasons(rainy and winter) with some modification and optimisation regarding insulation and water handling.

Keywords: Semi-circular solar water heater, Solar hour angle, Dripping pipe, Galvanized iron, Flat plate collector

Cite this paper: Vishwanath Nayak, Venkatesh Rao, Mallikappa, Eshwaraih, Design, Fabrication and Analysis of a Semicircular Solar Water Heater, Energy and Power, Vol. 6 No. 1A, 2016, pp. 22-27. doi: 10.5923/c.ep.201601.04.

Article Outline

1. Introduction

- The demand for energy across the world is increasing day by day. We are mainly depending on the fossil fuels for these energy demands. Fossil fuel burning results in emission of green house gases and other pollutants. Global warming and environmental pollution are the outcome of these emissions.There is a tremendous research going on in the entire world to search alternative sources of energy to fulfil the day-to-day energy needs and also future demands. In order to reduce the dependency on fossil fuels, importance towards solar energy is rapidly increasing in the world at present.Hot water has been used for domestic, industrial and household applications and; we are mainly depending on electricity, gas or coal for heating the water. Instead of using this, solar energy can be used for heating the water. India has great potential for utilization of solar energy for the different purposes like water heating, solar cooking, lighting etc.There are different types of solar water heaters that have been used efficiently around the world. Among them Flat Plate Collector’s (FPC) are important. But the cost of FPC’s is more and is difficult to afford in rural areas. And also retaining the water-hot for long period about 10-15 hours is a challenging task.In a study carried out by Zaeem M et.al [1], on improving the solar energy storage by using a hybrid energy storage system, they used hybrid system of water and paraffin in two tanks for storing the hot water. Comparison of this system with the individual water tank, energy gathering is optimized by hybrid system is 53.1% more and the energy recovery from the hybrid system increases to 59.9%. A study by Mangesh et.al [2], solar flat plate collector prepared by using locally available materials like plastic lateral tubes, HDPE pipe, glass wool, thermacol, plastic drum, G.I. sheet collector boxes by replacing copper tube, stainless steel water tank, thick PUF insulations, toughened glass can be able to get the hot water in the range of 55° to 65°. In a study by Mubeen N, et.al [3] a uniform velocity solar water heater by providing variable header for a conventional flat plate collector, is made to obtain uniform velocity. This is achieved by providing one end of the header to 5.08 cm and another end with 2.54 cm with the length of 100 cm. The study concludes with the increase in thermal performance and overall efficiency of the solar water heater. A study by Basil Ocafor et.al [4] on thermosiphon solar water heater, having 1.6 m2 area attained maximum of 72° temperature hot water and maximum efficiency of 42%. In a study carried out by T.V. Ramachandra et.al [5], on solar energy potential survey in Karnataka, reveals that Karnataka is located between 11°40' and 18°27' north latitude and the geographic conditions favors the harvesting of solar energy. Karnataka receives global solar radiation in the range of 3.8–6.4 kWh/sq.m. Global solar radiation during monsoon is lesser compared to summer and winter because of the dense cloud cover. The study identifies that the coastal parts of Karnataka with the higher global solar radiation is ideally suited for harvesting solar energy. Solar radiation level in Dakshina Kannada has 6.16, 3.89 and 5.21 kWh/sq.m during summer, rainy and winter seasons. In a study, B. Kalidasan et.al [6] described that, the efficiency of the flat plate collector increases with an increase in number of transparent covers and decreases after an optimum number of covers and also decreases with an increase in refractive index. Two transparent covers and lower refractive index gives higher efficiency. P. Sivakumar et.al [7] performed test for improving the performance of flat plate collectors. In this study, he proved that by increasing the number of riser tubes and by arranging them in zigzag pattern, the efficiency of flat plate collector increases. M Sridharan et.al [8] proved that performance of a solar flat plate collector can be increased by means of increasing contact surface area, changing tube materials of higher conductivity.Present work focuses on design and fabrication of semicircular solar water heater and how the efficiency will change with different conditions, materials and methods.In this project, water is heated in three setups. One is without insulation and collector; second one is with insulation and collector but without transparent cover and third one is with insulation, collector material and transparent cover.

2. Materials and Methods

2.1. Design and Fabrication of Semicircular Solar Water Heater

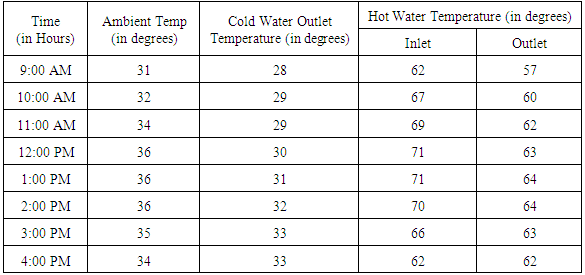

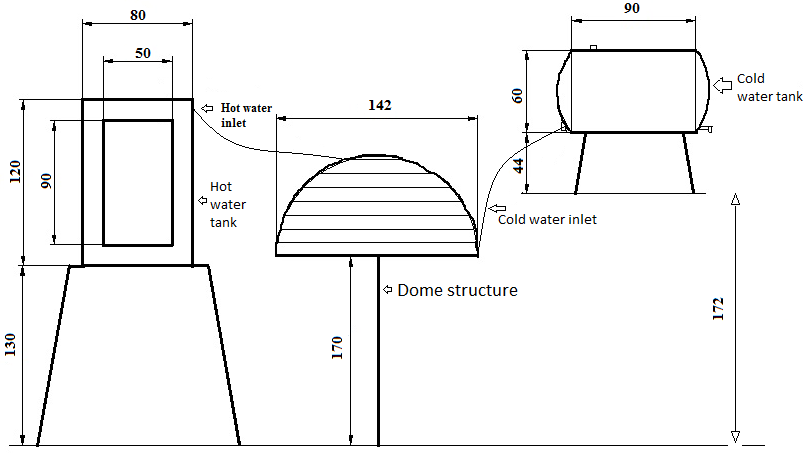

- The design data’s of the semicircular solar water heater is as below.Diameter of the semicircular trough=142 cm.Height of the dome=71cmTotal area of the collector plate=0.792m2Material used for collector plate=aluminium sheetInsulation used=coconut husk and hard paperOuter Diameter of the pipe=16 mmPipe thickness=1 mmType of pipe used=dripping pipe-Kaveri, ISICapacity of hot water storage = 150 litre’s. Figure 1 shows design of the dome set-up. By using above specifications, the dome structure, its base, stand for locating cold water drum and hot water drum has been prepared. Figure 2 Shows fabricated cold water stand and dome structure. These Structures are made by scrap material, and operations like cutting, welding and painting all are done at college workshop. In the morning at 10 am, the water flow to the hot water tank is made open and at evening 4 pm it will be closed.

| Figure 1. Design of the dome type set-up |

2.2. Set-up

- There are three setups used in this project. They are discussed here.

2.2.1. Set-up without Collector Plates and Insulator

- In the first setup as shown in figure 3, the dripping pipe is directly winded over the semicircular metallic structure. There is no insulation in between the pipe and the structure; pipe has direct contact with the structure material. There is very less gap between the pipe windings. And there is no transparent cover over the pipe. From the bottom of the cold water drum, water flows over the dome structure through the dripping pipe. Because of the density difference heated water in the pipe flows to hot water drum.

| Figure 3. Setup without insulator and collector |

2.2.2. Set-up with Collector and Insulator but without Transparent Cover over the Collector

- The figure 4 shows the setup with insulator and collector but without transparent cover. Here, the dome structure is insulated with board paper and over that aluminium sheet is fixed which acts as collector such that the heat from the collector will not pass to the dome structure. The collector is painted with dull black colour as the dull black is having good absorbivity and less reflectivity. The transparent cover is not used to trap the solar radiation. In this setup analysis has been one.

| Figure 4. Setup with insulator and collector but without transparent cover |

2.2.3. Set-up with Absorber Plate and Insulator with Transparent Cover

- Figure 5 shows the set-up with blackened collector and insulator with transparent cover. The dome type structure is insulated by using the board paper and over that aluminium sheet has been fixed in required shape. This aluminium sheet is painted with dull black to absorb maximum amount of solar radiation. Over that 24 turns of dripping pipe is wounded. The cold water flows in this pipe from the bottom of the cold water tank. Top side of the dripping pipe is connected to the hot water tank. A plastic transparent cover has been covered over the pipe to prevent the heat losses from the collector. Due to solar radiation, water inside the pipe starts heating and flows upward and then gets collected in the hot water tank. Maximum of 72°C is attained in this set-up during the 12-2pm.

| Figure 5. Set-up with blackened collector and insulator with transparent cover |

3. Results and Discussion

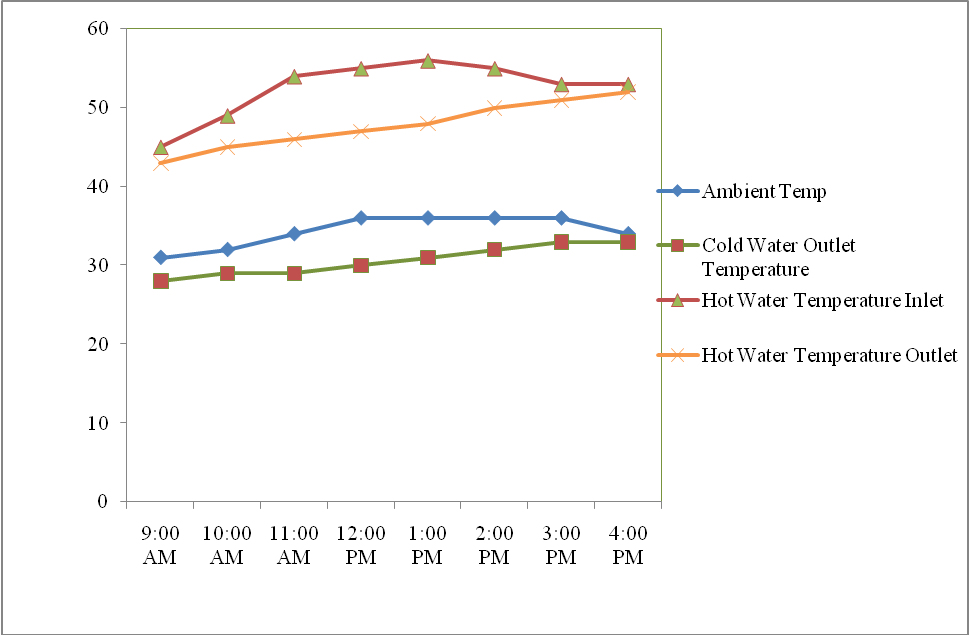

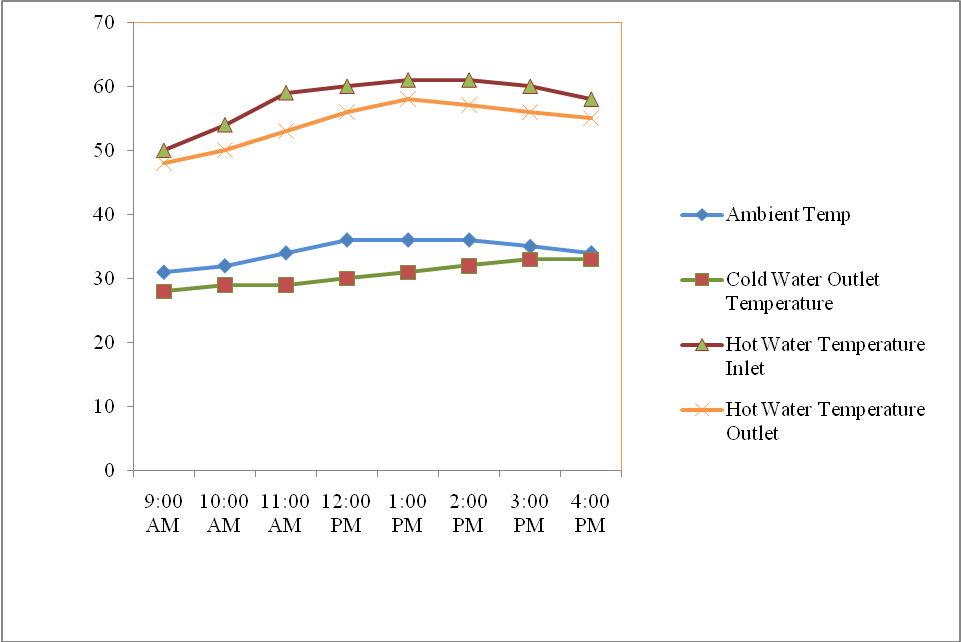

- After the design and fabrication, experimentation has been done for the time duration of two months. The received results are discussed as below. In the first set-up, dripping pipe is wounded over the dome structure without any insulation and absorber material. Graph 1 shows the inlet and outlet temperatures of the water from the cold and hot water tanks.

| Graph 1. Temperature variation in the Setup without Insulation, Absorber Material, Transparent Cover |

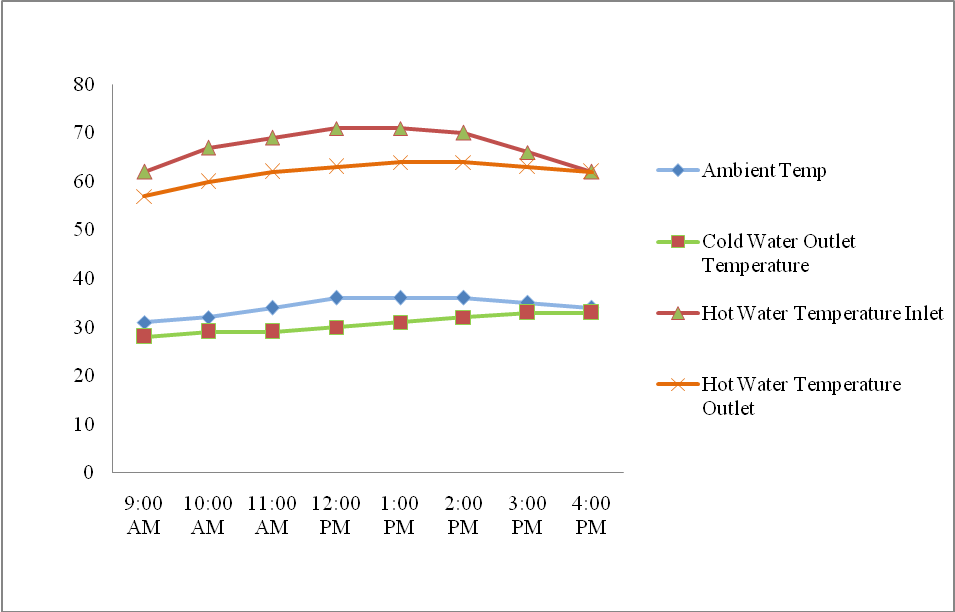

| Graph 2. Temperature variations in the setup with insulation, absorber material but without transparent cover |

|

| Graph 3. Temperature variation in the setup with insulation, absorber material without transparent cover |

4. Conclusions

- By studying above three set-ups, it has been concluded that, the semicircular or dome type structured solar water heater having area of 0.792 m2 with insulation, black absorber plate and transparent cover over the pipes gives maximum temperature of hot water up-to 72°C in the mid-noon, and for this 50-55°C of hot water is attained for next day morning. In the setup with just winding dripping pipe on the structure, without transparent cover over it, a temperature of 56°C is attained in the dripping pipe. This is because of the absence of absorber material and the transparent cover. The setup with insulation over the structure and blackened plate winded with dripping pipe but without transparent cover gives the temperature of 61°C in the mid-noon. This is because the hot absorber metal surface receives maximum amount of heat, part of that is given to the dripping pipe and more amount of heat is wasted.Since this work is a ongoing project, the third set-up should be studied further for more time in summer and other two seasons(rainy and winter) with some modifications and optimisation regarding insulation and water handling, some more time is required to give the final conclusion.

ACKNOWLEDGEMENTS

- We thank Dr. Rajkiran Ballal, Principal, MMCT and S.I Nathan, Chairmen CMC Group of Institutions for providing and sanctioning additional facilities for this work.We would like to express our heartfelt thanks to Gunapal, Tukaram, Rajshekhar and Harish for their guidance and co-operation.We would also like to express our heartfelt thanks to our students Jaswanth, Harish, Girish, Srajan, Ravi Desai, Vikas, Sharath, Gurusidda for their assistance in this work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML