Krishna Kini H., Hanock S. Dsouza, N. Satheesh Kumar

Department of Mechanical Engineering, Canara Engineering College, Mangalore, India

Correspondence to: N. Satheesh Kumar, Department of Mechanical Engineering, Canara Engineering College, Mangalore, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

As the petroleum resources are diminishing, it is the need of the hour to go for an alternative. Fuels Derived from the seeds is one of the best alternative for Diesel. This paper gives a detailed overview about the properties, performance and emission characteristics of blends of Castor and Pongamia Pinnata biodiesel in blend proportion of B20P, B15P5C, B10P10C, B5P15C, B20C. Experiments were conducted on a single cylinder, 4 stroke, water cooled CI engine running at the speed of 1500rpm, at a compression ratio of 16.7:1 and at an injection pressure of 205 bar. Based on properties it was found that density, kinematic viscosity, gross calorific value, flash and fire point was higher compared to diesel, pH was found to be neutral. From the experimental analysis it was found that emission characteristics like CO2, CO and HC were found to be decreased and NOx emission was increased in comparison to diesel and performance characteristics like Exhaust gas temperature was higher for diesel, BTE and SFC was higher for biodiesel, BP remained almost same for both. Based on the results and analysis it was concluded that blend B5P15C is an optimum blend among all 5 blends.

Keywords:

Biodiesel, Pongamia Pinnata, Castor, Properties, Performance, Emission, CI engine

Cite this paper: Krishna Kini H., Hanock S. Dsouza, N. Satheesh Kumar, Investigation of Properties of Different Blends of Castor and Pongamia Biodiesels and Their Performance in a Compression Ignition Engine, Energy and Power, Vol. 6 No. 1A, 2016, pp. 8-14. doi: 10.5923/c.ep.201601.02.

1. Introduction

Energy is the most fundamental requirement for human existence. Consumption of fossil fuels has highly increased and the use of these energy resources has major environmental impact as well. Diesel fuel is largely used in transport, agriculture, commercial, domestic and industrial sectors for the generation of mechanical energy and electricity. Out of all the alternative fuels available, bio-diesel obtained from vegetable oils and animal fatty acids promises to be more eco-friendly when compared to diesel fuel [1].The concept using vegetable oil as a fuel dates back to 1895 when Dr. Rudolf Diesel developed the first diesel engine to run on vegetable oil. Rudolf Diesel Stated: “The use of vegetable oil for engine fuels may seem insignificant today. But such oil may become in source of time as important as petroleum and the coal tar products of the present time”. Biodiesel is used in diesel engines and heating systems. Thus this fuel could be considered as mineral diesel substitute that having an advantage of reduction in greenhouse gases because it is renewable resource [2].A biofuel is a fuel that is produced through contemporary biological processes, such as agriculture and anaerobic digestion, rather than a fuel produced by geological processes such as those involved in the formation of fossil fuels. With depletion of fossil fuels there is a need to find alternative fuels and bio diesel is one such example. Bio diesel is defined as mono-alkyl esters of long chain fatty acids derived from vegetable oils or animal fats and alcohol with or without a catalyst. It is environmental friendly, non-toxic, renewable and eco-friendly fuel [3].Sritar K et al [4] conducted an experiment on mixture of two biodiesel from pongamia pinnata oil and mustard oil and they were blended with diesel at various mixing ratios. The effects of dual biodiesel on engine performance and exhaust emissions were examined in a single cylinder, direct injection, air cooled and high speed diesel engine at various engine loads with constant engine speed of 3000 rpm. The influences of blends on Carbon Monoxide (CO), Carbon di-oxide (CO2), Hydrocarbons (HC), Oxides of Nitrogen (NOx) and smoke opacity were investigated by emission tests. Based on results dual biodiesel blends gave higher smoke opacity, HC and NOx than diesel. But for the Blend A of 90% diesel+5% Pongamia+5% Mustard, Blend B of 80% diesel+10% Pongamia+10% Mustard and Blend C of 60% diesel+20% Pongamia+20% Mustard the smoke opacity was nearer to diesel. It was concluded that dual biodiesel blends of Blend A, Blend B and Blend C, would be used as an alternative fuel for diesel in the diesel engines.S. Ganesan et al [5] conducted an experiment on single cylinder 4.4kW, 1500 rpm Kirloskar C.I. engine. Blends considered were B30 i.e.70% Diesel+15% Castor + 15% Ethanol and 70% Diesel+ 10% Castor +20% ethanol. The result showed that Sample of 70%Diesel+ 10%Castor+ 20% Ethanol has lower value of NOx, unburnt HC, exhaust gas temperature and brake thermal efficiency than Diesel.Shankarappa Kalgudi et al [6] conduced an experiment on performance and emission tests on single cylinder, 4 stroke water cooled engine at constant speed of 1500 rpm and compression ratio of 16.5:1 for B20 (5H+15C+80D) and B25 (5H+20C+75D) blends of karanja and cottonseed biodiesel. The experimental result showed that performance characteristics like brake power (BP), brake specific consumption (BSFC), brake thermal efficiency (BTE) and emissions characteristics for the hybrid blends are better than the D100. Hence these two blend blends of Karanja oil biodiesel and Cotton seed oil biodiesels can be used as a vehicular fuel in CI engines.T. Venkateshwara Rao et al [7] conducted an experiment to investigate the properties, performance and emission of different blends (B10, B20 and B40) of Pongamia, Jatropha and Neem. The test result indicated that B20 has closer performance to diesel and reasonable efficiency, lower smoke, CO and HC. Pongamia biodiesel gives better performance compared to Jatropha and neem biodiesel.Based on the literature review it was observed that:1. Blends up to B20 blends gives optimum results for use in compression ignition engine. 2. The papers on mixing of biodiesel especially with castor and Pongamia were limited3. The blends of bio diesel show higher brake thermal efficiency, lower exhaust gas temperature, Lower CO, CO2, HC but there will be increase in NOx emissionThe main objective of the experiment is to study the properties of different B20 Blends which are listed as followsB20P: 20 % Pongamia + 80% DieselB15P5C: 15% Pongamia + 5% Castor+ 80% DieselB10P10C: 10% Pongamia + 10% Castor + 80% DieselB5P15C: 5% Pongamia + 15% Castor + 80% DieselB20C: 20% Castor + 80% DieselAnd to examine the performance and exhaust analysis of all 5 B20 Blends.

2. Preparation of Biodiesel Sample

This section gives a detailed overview about preparation of biodiesel and blending to obtain the samples.

2.1. Seed Collection and Oil Extraction

The seeds of Pongamia were collected from local shops.The seeds were then put in decorticator to remove shells. The seeds is then passed into mechanical oil extractor and filtered to get Pongamia oil. In case of castor the oil was purchased from the local shop.

2.2. Checking of Free Fatty Acid (FFA) Content of Oil

Before transesterification, Free Fatty Acid content is calculated by titrating N/10 NaOH against mixture of (10gms of oil + 50ml isopropyl alcohol+ 2-3 drops of phenolphthalein indicator)FFA Content = 28.2 * (Normality of NaOH) * (Titration value) / (weight of oil)If FFA is found to be below 4%, Single stage (Alkali based) process has to be undertaken. If FFA is found above 4%, Double stage (Acid based + Alkali based catalyst) process has to be undertaken.For Castor FFA content was found to be 2.8% and for Pongamia it was found to be 3.5% which indicates that both are single stage process.

2.3. Single Stage Transesterification

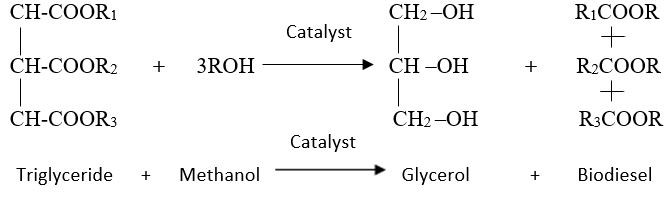

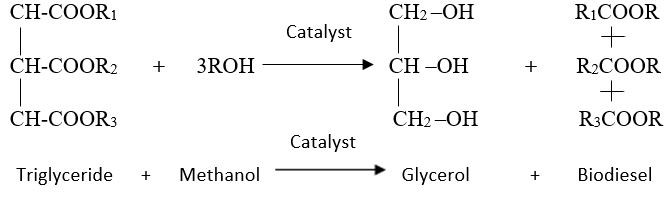

Transfer 1 liter of oil in to 3 neck flask and place it on magnetic stirrer and connect condenser and thermometer. Take 300 ml methanol+ Add NaOH (6.3g for Castor and 7g for Pongamia), pour it into 3 neck flask and maintain temperature to 60-63°C for 2 hours. Glycerin will settle at bottom and needs to be separated. After esterification methanol has to be recovered by heating the biodiesel to 70°C and cooling. Then the sample has to be washed with warm water to remove soap content present in sample. The above oil extraction and transesterification was done at District Bio Diesel Centre at NIT, Karnataka. | Figure 1. Chemical reaction of transesterification |

| Figure 2. Batch reactor |

| Figure 3. Separating vessel |

| Figure 4. Blends B20P, B15P5C, B10P10C, B5P15C, B20C |

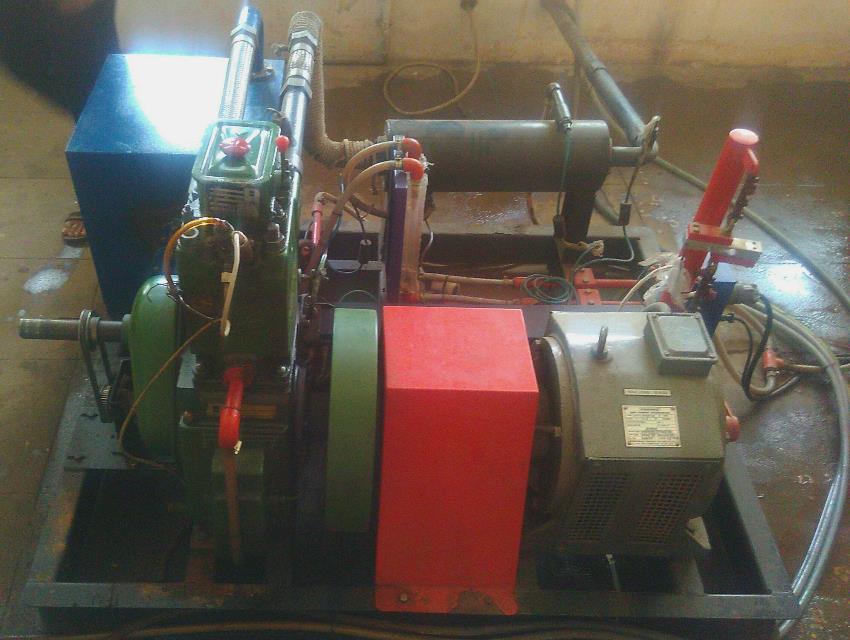

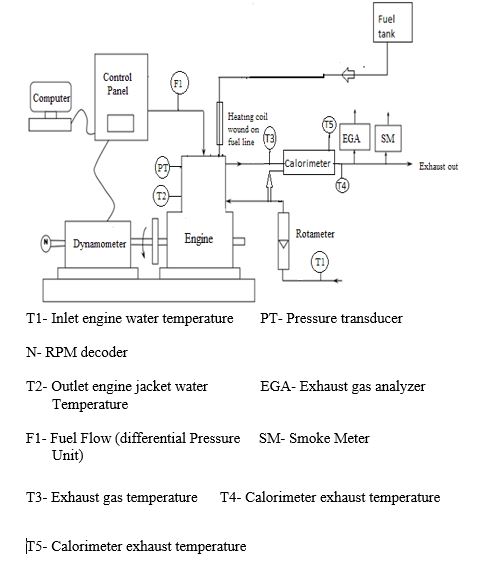

3. Experimental Procedure for Testing on Engine

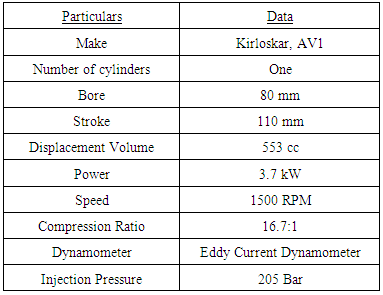

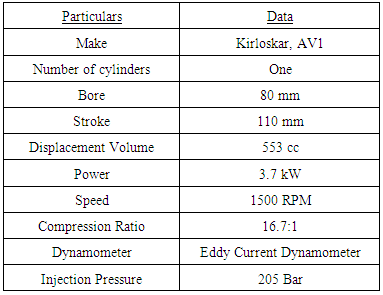

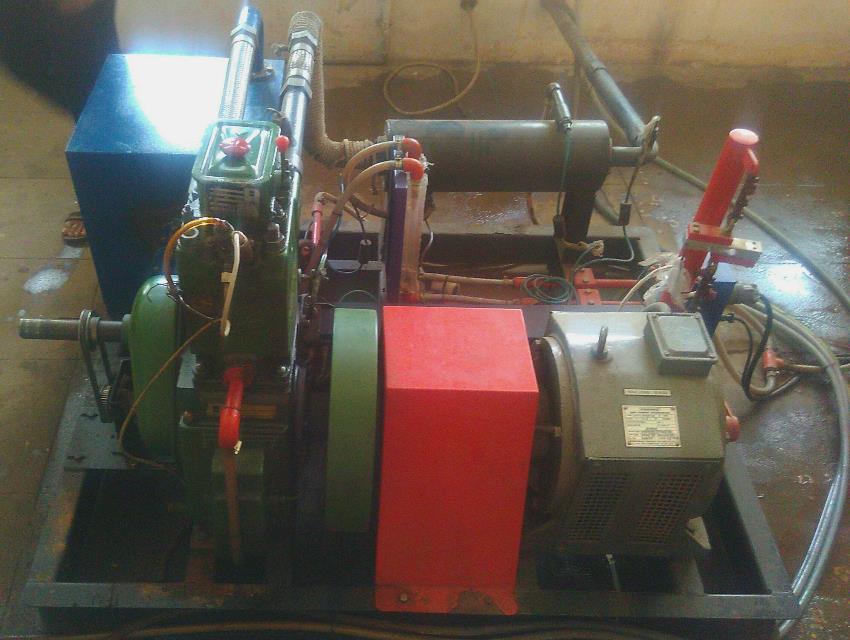

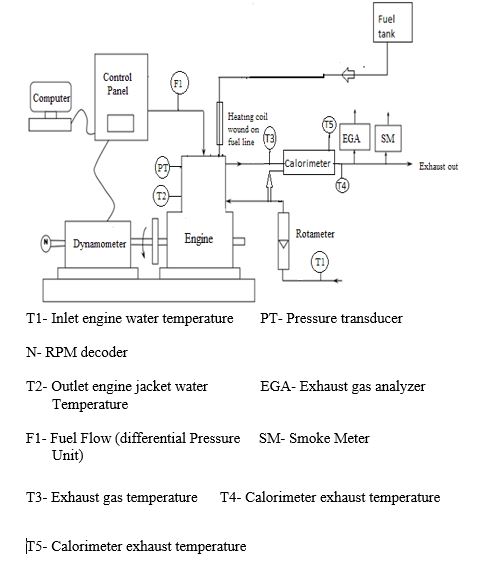

A four stroke, computerized single cylinder, water cooled diesel engine is used for the experiment maintained at 1500 rpm. The engine is attached at one end to the eddy current type dynamometer with a drive shaft coupling flange for loading. A throttle is used to control and increase the speed of the engine as the control variable. The dynamometer and engine is cooled by continuous supply of water to dissipate the generated heat. The other end of the dynamometer is hooked up to the digital readout system which contains the digital RPM meter, flow meter, oil sump temperature so that experimental readings can be obtained. The Engine is directly coupled to an eddy current dynamometer that is used for loading and the dynamometer were interfaced to a control panel, which is connected to a digital computer, used for recording test parameters like fuel flow rate, temperatures, load and for calculating the engine performance like brake thermal efficiency, brake power, brake specific fuel consumption, volumetric efficiency. Exhaust gas analyzer is used to calculate the emission parameters like CO, CO2, O2, NOx and HC. The calorific value and the density of the particular fuel is fed to the software for calculating the above said performance and exhaust parameters.The engine was started by hand cranking with diesel fuel supply and it is allowed to get its steady state. Water to engine cooling jacket is maintained at about 80 lph and water flow pressure is maintained by 0.25 HP external water pump.The testing on Engine was done at Tontadarya college of Engineering, Gadag Table 1. Specification of Engine

|

| |

|

| Figure 5. Kirloskar AV1 Engine |

| Figure 6. Schematic diagram of experimental test rig |

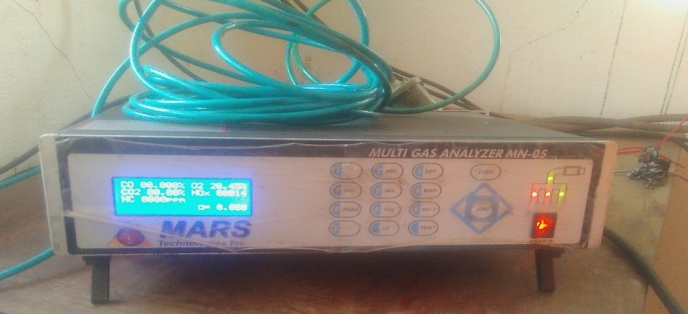

| Figure 7. Exhaust gas analyzer |

4. Results

4.1. Physical and Chemical Properties

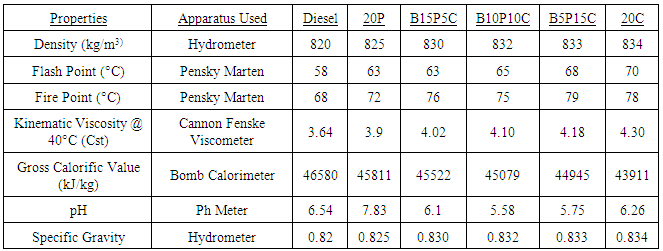

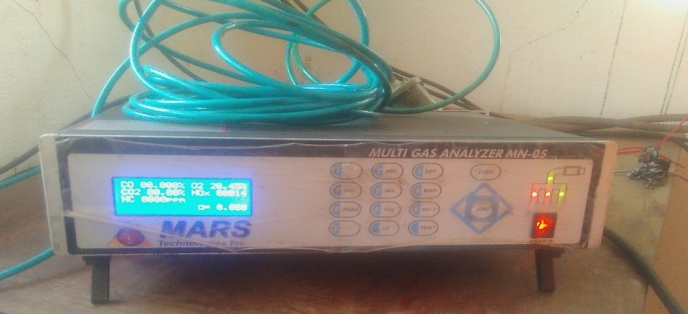

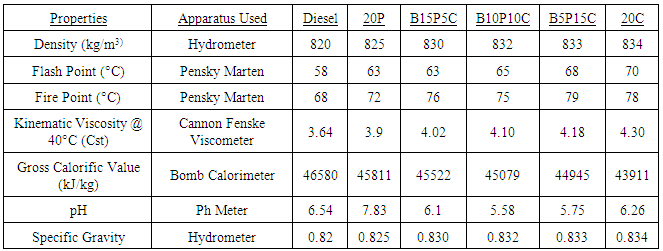

1) DensityDensity of the B100 biodiesel must be as close to the pure diesel so that blending becomes better. Density of B20 blends are more close to the density of pure diesel as the percentage of the biodiesel is less in the blend. B20P has density closer to that of Diesel. If there is a large variation in density, the fluids separate out from each other forming two different layer of fluids. It has been observed that Bio diesel has higher density than petroleum diesel which means that volumetrically-operating fuel pumps will inject greater mass of biodiesel than conventional diesel fuel. This in turn will affect the air−fuel ratio hence the local gas temperatures and NOx emissions increases.2) Flash and Fire PointFlash point and fire point of the fuel must be higher so that the fuel doesn’t catch fire during storage. Hence, to be on safer side, the preferred flash point values must be above 110°C for B100. From the graph it is evident that diesel has lesser value of flash point in comparison with Blends because diesel is less volatile when compared to biodiesel.3) Kinematic ViscosityThe viscosity of the biodiesel must be in the range of 3-6 centistokes. Higher viscosity leads to less accurate operation of the fuel injectors because of which there is poor atomization and increase in fuel droplet size. But in mean time fuel leakages will be reduced and that also leads to higher injection pressures.4) Gross Calorific ValueThe calorific value of pure diesel is 46580 KJ/KG. The calorific value will directly affect the efficiency of the fuel as it gives the amount of heat of combustion. The oxygen is generally 10-12% in biodiesel because of which it has lower energy density and heating value, so it needs more amount of fuel to be injected for same Engine power output.5) pHThe pH value is found to be nearer to that of neutral value of 7, Hence pH for all the sample and diesel is neutral.

4.2. Performance and Emission Characteristics

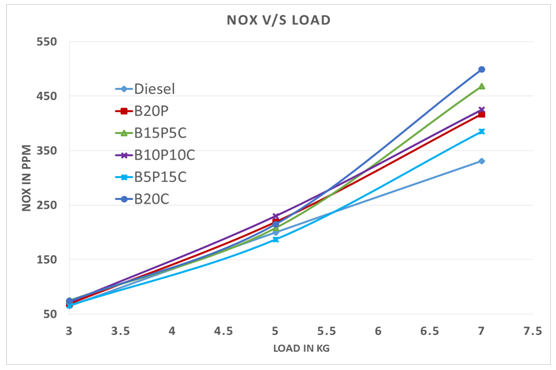

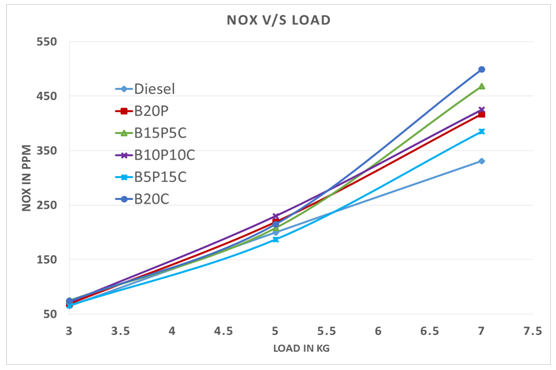

1) Oxides of Nitrogen (NOx) vs Load | Figure 8. NOx vs Load for various Blends |

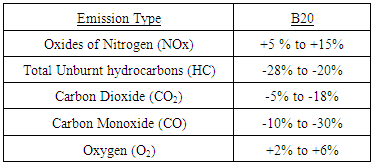

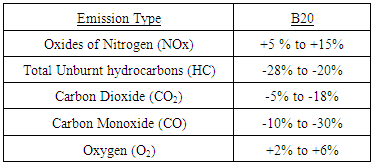

From the graph it is observed that the NOx emission increases with increase in the load. It was found that NOx emission was found to be maximum for 20% castor and minimum for diesel. NOx emission is increased because of more amount of the oxygen in biodiesel due to which more amount of nitrogen reacts with the oxygen to form NOx. Also Density also has an effect on NOx emission i.e. bio diesel has higher density which causes more amount of fuel to be sprayed into the combustion chamber as a result of which NOx increases. This has adverse effect on the atmosphere causing smog and acid rain however the NOx can be reduced by using catalytic converter or by delaying the ignition timing or by using additives.Table 2. Properties of B20 Blends and Diesel

|

| |

|

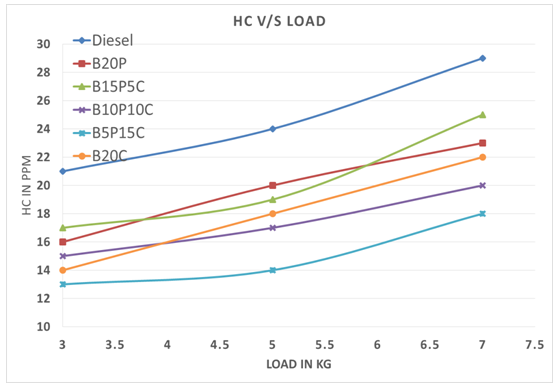

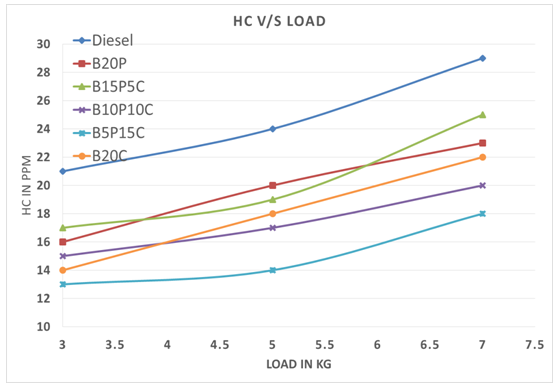

2) Hydrocarbons (HC) vs Load | Figure 9. HC vs Load for various Blends |

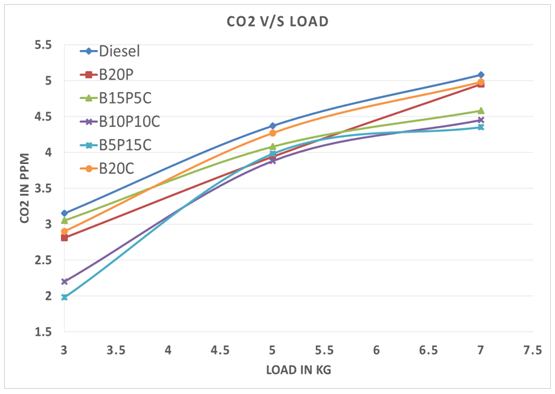

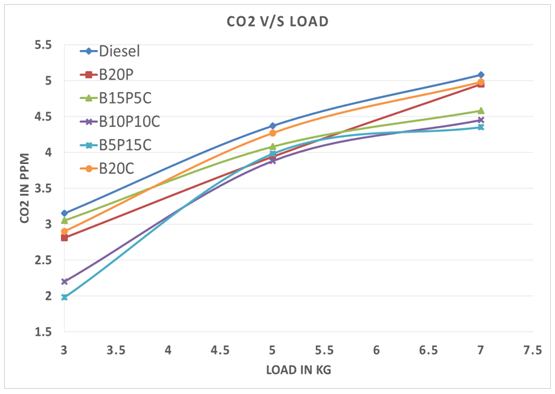

From the graph we can observe that the emission of HC was found maximum for diesel and found to be minimum for B5P15C at all loads. HC emissions found to increase with the load. Decrease in HC emissions is also caused by the cetane number. Higher cetane number of biodiesel will reduce the burning delay, which in turn results in the HC emissions reduction. Addition of small amount of methanol and ethanol with biodiesel and its blends with diesel may again reduce HC emissions.3) Carbon Di- Oxide (CO2) vs Load | Figure 10. CO2 vs Load for various Blends |

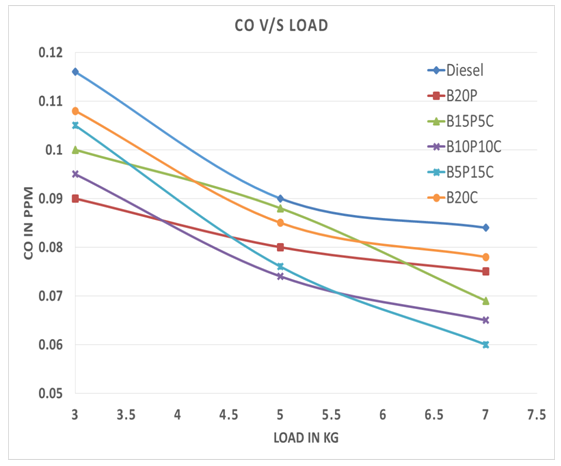

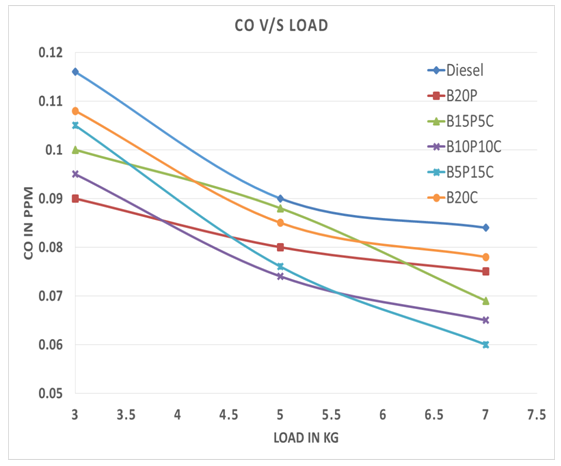

From the graph we can find that emission of CO2 is maximum for diesel and decrease with biodiesel blends and emission of CO2 was found to be minimum for B5 Pongamia+ B15 Castor at 7kg of load and it was 30% less than that of diesel. Biodiesel results in fewer amounts of CO2 emissions than diesel during combustion due to the lower carbon to hydrogen ratio.4) Carbon Monoxide (CO) vs Load | Figure 11. CO vs Load for various Blends |

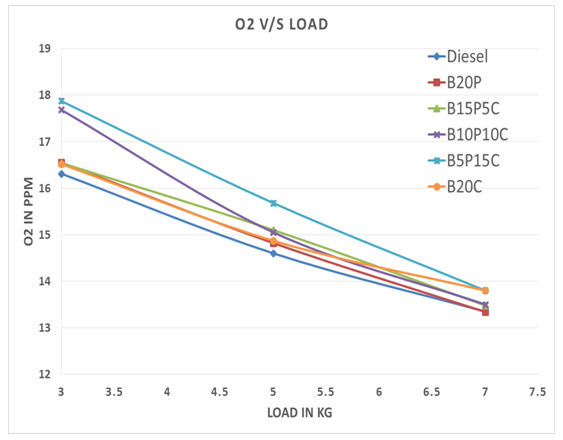

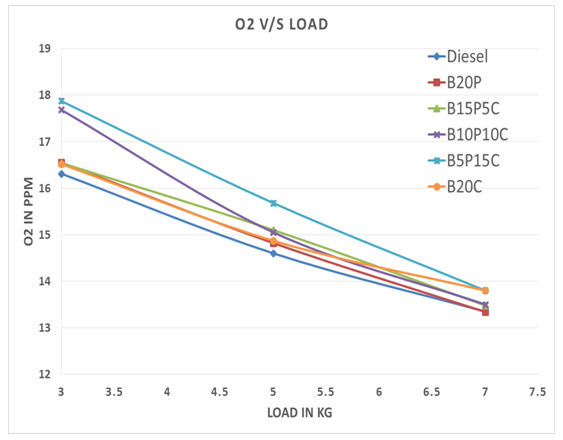

From the graph we can see that CO emission was found to decrease for biodiesel blends and it is found that CO emission at 7kg load is minimum for B5P15C. With amount of pure biodiesel is increased in blends; CO emissions of blends will reduce because of increase in oxygen content which is because of less calorific value. CO emissions for biodiesel decrease with an increase in engine speed and load. 5) Oxygen (O2) vs Load | Figure 12. O2 vs Load for various Blends |

From the graph we can observe that emission of O2 increases for biodiesel blends when compared to diesel and O2 emission was found maximum for B5 Pongamia+B15 Castor. The emission of O2 increased due to the high amount of oxygen content in the biodiesel which is in the range of 10-12% by volume which is because of higher density of biodiesel.Table 3. Comparison of Exhaust gas for Diesel and B20 Blends of biodiesel

|

| |

|

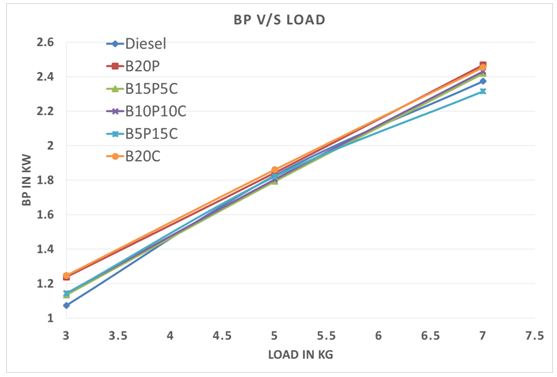

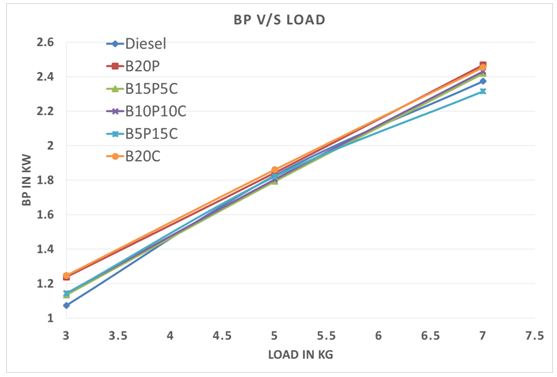

6) Brake Power (BP) vs Load | Figure 13. BP vs Load for various Blends |

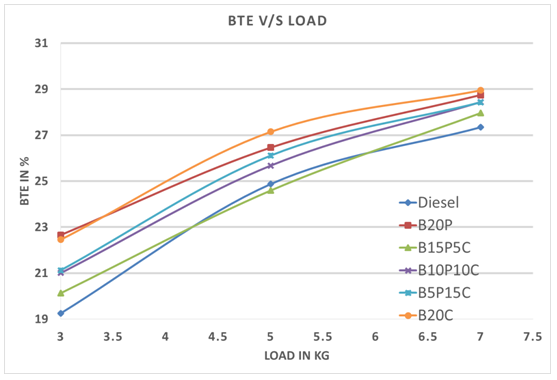

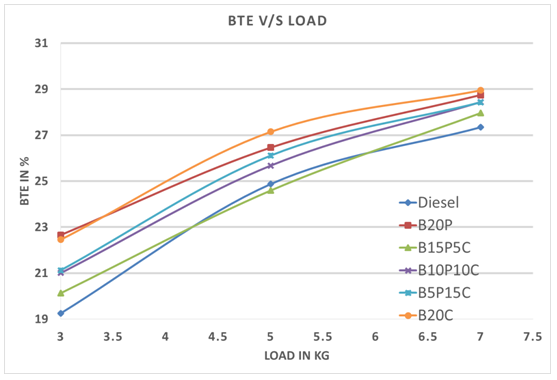

From the graph we can observe that BP increases as the load is increased. The value of BP is found to be 14% more for 20% castor biodiesel when compared to conventional diesel. Biodiesel has lower energy density and heating value, so it needs more amount of fuel to be injected for same Engine power output, therefore BP remains almost same.7) Brake Thermal efficiency (BTE) vs Load | Figure 14. BTE vs Load for various Blends |

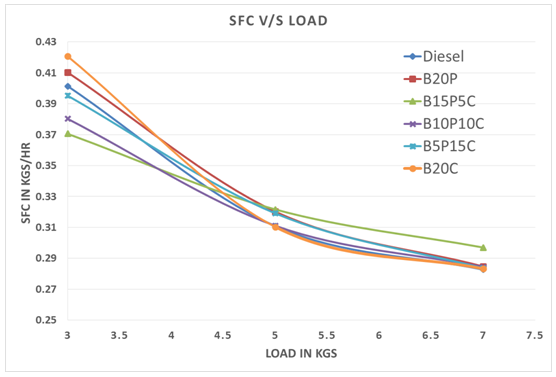

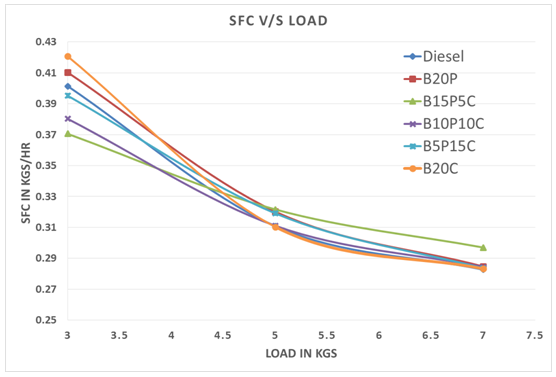

From the graph we can observe that as load is increased there will be increase in the BTE. The reason for BTE to remain constant for each load is that a relatively less portion of the power was lost with the increase in engine load. The reason for increasing trend in BTE is because of better combustion due to inherent oxygen, higher cetane number and also less SFC at higher loads. The value of BTE is found to be maximum for 20% castor and minimum for diesel. On an average value of BP for 20% castor biodiesel was found to be 10% more than the conventional diesel.8) Specific Fuel Consumption (SFC) vs Load | Figure 15. SFC vs Load for various Blends |

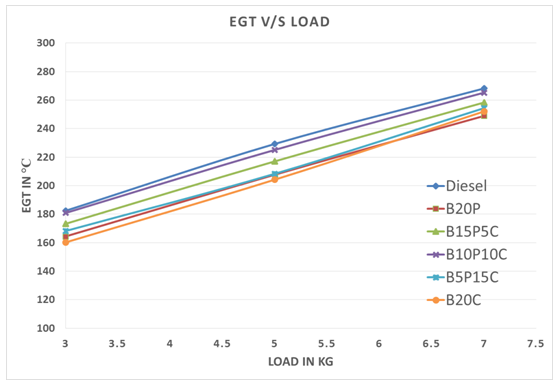

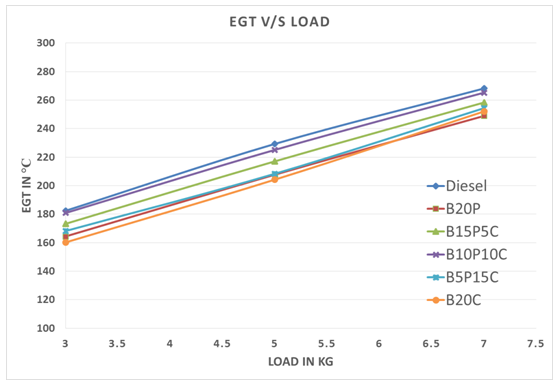

From the graph we can observe that as load is increased specific fuel consumption will decrease. We can observe that pure blends have almost similar SFC value as that of diesel. As proportion of mixed oil is increased in the blends, viscosity will increase which in turn increases specific fuel consumption due to poor atomization of the fuel. In order to maintain same Brake power, more amount of fuel has to be injected which is because of higher density and Higher Flash and fire point.9) Exhaust Gas Temperature (EGT) vs Load | Figure 16. EGT vs Load for various Blends |

From the graph we can observe that as the load is increased EGT will increase. The exhaust gas temperature was found to be on average 11% greater for diesel at all loads when compared to biodiesel. The reason for higher exhaust gas temperature was poor atomization of vegetable oil due to higher viscosity which causes slow combustion and part of the oil supplied may burn late in cycle. And also there occurs incomplete combustion in the cylinder at high load which intern causes increase in temperature of exhaust gas. Exhaust gas temperature can be reduced by using additives.

5. Conclusions

Based on Property testing it was found that• Density of all samples was found to be near to that of diesel, with diesel being the least at 820 kg/m3• Flash and fire point was higher for biodiesel samples, with highest flash point for B20C at 70°C for 20C and highest fire point for B5P15C at 79°C.• Calorific value was found to be lower compared to diesel, with diesel being highest at 46580 kJ/kg.• pH shows that biodiesel are neutral in nature. Based on the Exhaust and performance analysis it was found that• NOx emission was found to be higher for bio diesel with least being for B5P15C at 385 ppm compared to 331 ppm for diesel at higher loads. • HC emission was higher for diesel in comparison to blends of bio diesel with least for B5P15C biodiesel at 18 ppm compared to diesel at 29 ppm at higher loads.• CO2 emission for biodiesel is lower in comparison to diesel, with lest being for B5P15C at 4.35 ppm compared to diesel at 5.08 ppm at higher loads.• CO emission for biodiesel is lower in comparison to diesel, with lest being for B5P15C at 0.06 ppm compared to diesel at 0.084 ppm at higher loads.• O2 Emission for bio diesel was higher with highest for B5P15C at 13.8 ppm compared to diesel at 13.35 ppm at higher loads.• Brake power remains almost same for diesel and bio diesel• Exhaust gas temperature was found to be higher for diesel at 268°C than Bio diesel with least being for B20P at 248ºC at higher loads.• Brake thermal efficiency was higher for biodiesel than diesel with highest for B20C at 28.9% compared to diesel at 27.3% at higher loads.• Specific fuel consumption remains almost same at higher loads.Based on the results and analysis it can be concluded that blend B5P15C is an optimum blend among all 5 blends. This results in lower greenhouse gas emission with increased efficiency with same fuel consumption, thus saving our dependence on fossil fuels to a certain extent.

References

| [1] | K. Nantha Gopal and R. Thundil Karupparaj, Effect of pongamia biodiesel on emission and combustion characteristics of DI compression ignition engine, Ain Shams Engineering Journal, pp. 297–305, 2015. |

| [2] | Chavan S.B., Kumbhar R.R. and Deshmukh R.B., Callophyllum Inophyllum Linn (“honne”) Oil, A source for Biodiesel Production, Research Journal of Chemical Sciences, ISSN 2231-606X, Vol. 3(11), 24-31, November (2013). |

| [3] | A. E. Atabani, A. S. Silitonga, H. C. Ong, T. M. I. Mahlia, H. H. Masjuki, Irfan Anjum Badruddin and H. Fayaz, Non-edible vegetable oils: A critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production, Renewable and Sustainable Energy Reviews, ISSN: 2571–9855, Pages 211-245. |

| [4] | K. Srithar, K. Arun Balasubramanian, V. Pavendan and B. Ashok Kumar, Experimental investigations on mixing of two biodiesels blended with diesel as alternative fuel for diesel engines, Journal of King Saud University – Engineering Sciences (2014), Available: http://dx.doi.org/10.1016/j.jksues.2014.04.008. |

| [5] | S. Ganesan and Dr. A. Elango, Performance Analysis of CI Engine using blends of Castor Oil and Ethanol, IJMMME, Volume 1, Issue 1 (2013) ISSN 2320–4060 (Online). |

| [6] | Shankarappa Kalgudi and K V Suresh, An Experimental Study of Performance And Emission Characteristics of CI Engine Fuelled With Hybrid Blends Of Biodiesels, IJTRA, e-ISSN: 2320-8163, Volume 2, Issue 5 (Sep-Oct 2014), PP. 71-74. |

| [7] | T. Venkateswara Rao, G. Prabhakar Rao and K. Hema Chandra Reddy, Experimental Investigation of Pongamia, Jatropha and Neem Methyl Esters as Biodiesel on C.I. Engine, Volume 2, Number 2, Jun. 2008, ISSN 1995-6665, Pages 117 – 122. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML