-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2015; 5(1A): 15-18

doi:10.5923/c.ep.201501.04

Effect of Compression Ratio on the Performance and Emission Characteristics of CI Engine for a Blend of Soapnut Oil, Cottonseed Oil Methyl Ester and Diesel

Vinoothan Kaliveer , Rolvin S. D’Silva , Prashanth Kumar, K. Raju

Department of Mechanical Engineering, St Joseph Engineering College, Mangaluru, India

Correspondence to: Prashanth Kumar, K. Raju , Department of Mechanical Engineering, St Joseph Engineering College, Mangaluru, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

In the present work, soap nut oil, cotton seed oil methyl ester and diesel were blended in the proportion of 10:15:75 by volume to form a bio diesel blend of B25. It has been observed that the calorific value is lower and viscosity is higher for B25 as compared to diesel. The performance and emission characteristics were studied using a variable compression ratio diesel engine test rig for three different compression ratios of 17, 17.5 and 18. The results showed that the brake thermal efficiency has increased by 5.2% at a compression ratio of 18 compared to the brake thermal efficiency at a compression ratio of 17. Brake specific fuel consumption has decreased by 4.7% with the increase in compression ratio. However the brake thermal efficiency for B25 is lower than that of diesel. It has been observed that the NOx emissions are higher by 2% and hydrocarbon emissions and smoke opacity are lower by 55.5% and 12.4% respectively for B25 as compared to diesel at full load.

Keywords: Soap nut oil, Cotton seed oil, Methyl ester, Diesel, Brake thermal efficiency

Cite this paper: Vinoothan Kaliveer , Rolvin S. D’Silva , Prashanth Kumar, K. Raju , Effect of Compression Ratio on the Performance and Emission Characteristics of CI Engine for a Blend of Soapnut Oil, Cottonseed Oil Methyl Ester and Diesel, Energy and Power, Vol. 5 No. 1A, 2015, pp. 15-18. doi: 10.5923/c.ep.201501.04.

Article Outline

1. Introduction

- With increasing concern about fuel shortage and air pollution control, research on improving and reducing exhaust emissions has become the major topic in combustion and engine studies. There may be various sources of energies namely, renewable, fossil, and fissile. The fossil energy includes natural gas, petroleum, coal etc.The use of fossil fuels raises serious environmental concerns. Burning of fossil fuels produces 21.3 billion tons of carbon dioxide per year leading to global warming [1]. Because of the depletion of world petroleum reserves it results in two problems, namely, an increase in fuel prices and global warming.An intensive search for new alternative fuels due to depleting petroleum reserves and increasing cost of the petroleum products, has almost reached the wide spread use of bio-fuel and this was restrained from its use in CI engine [2]. It is being taken into account by systematic efforts from many researchers to determine the suitability of vegetable oil and its derivatives as fuel or additives to the diesel [3-6]. The current mandates regarding the use of biodiesel around the world mostly operate on a biodiesel blend. The use of edible oils for biodiesel production may be contrary to current social movements and energy policies. Non edible vegetable oils, which are mostly produced by seed bearing trees and shrubs, could be an alternative oil source and also the best feedstock for biodiesel that does not affect the edible oil market [7]. The different biodiesel blends will also differ from each other and from pure biodiesel. B5 will differ in performance and emissions from B20 [5-7]. Thus, there is a significant potential for non-edible oil source from different plants for biodiesel production as an alternative to petroleum.

2. Fuel Sample Used for CI Engine

2.1. Soapnut Oil

- Soapnut is a fruit of the soap nut tree generally found in tropical and subtropical climate areas including Asia, America, and Europe. The scientific name of soapnut oil is sapindus mukorossi. It is found in India, Nepal, Bangladesh and Pakistan. Soapnut trees naturally grow in deep clay loam soil and flourish in areas with annual rainfall of 150-200 cm where they prevent soil erosion. The seed is enclosed in a black, smooth and hard globe endocarp [8]. Soapnuts contain saponins, a natural surfactant and have been used as detergent [9] which is substituted for washing soap and is as such used in preparation of quality shampoos, detergents, etc. Soapnut seeds contain 23% oil of which 92% are triglycerides [10].

2.2. Cotton Seed Oil Methyl Ester

- Cotton seed oil is extracted from the cotton plant seeds of different species like Gossupium hirsutum and Gossypium herbaceum. It is one of the second best potential sources for plant proteins after soybean and the ninth best oil producing crop. Cotton seed oil contains significant amounts of saturated fatty acids, palmitic acid (22 – 26%), as well as traces of Myristic, arachidic and behenic acids, lesser amount of monounsaturated fatty acids, oleic (15 – 20%). The properties of cotton oil are very close to diesel. Cotton seed has a high cetane number of 45 and flash point of cottonseed oil is 229°C whereas diesel is 62.5°C [11]. Cotton seed oil methyl ester as a fuel in a direct diesel engine showed an improvement in the thermal efficiency, smoke opacity was reduced and NOx emissions were increased [12]. For the present study, a blend of B25 was prepared by mixing 10% by volume soapnut oil, 15% by volume cottonseed methyl ester and 75% diesel fuel.

3. Experimental Details

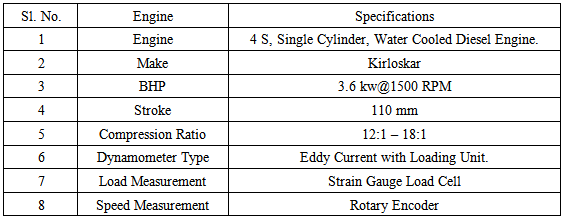

- The experimental setup consists of a single cylinder four stroke, water cooled diesel engine. The detailed specifications of engine are given below

|

3.1. Physico-Chemical Properties of Fuel Samples

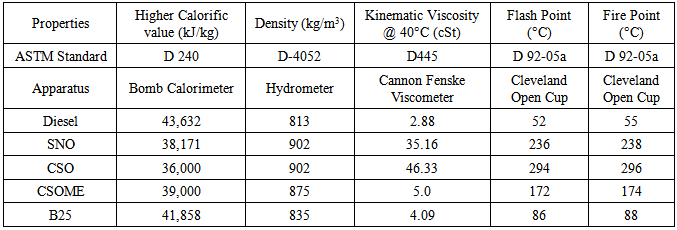

- The Physico-Chemical properties of soapnut oil (SNO), cottonseed oil (CSO), cottonseed oil methyl ester (CSOME) and diesel were determined and tabulated in Table 2.

|

4. Results and Discussion

- Engine tests were conducted using blend of SNO and CSOME with diesel (B25) in order to study its effect on engine performances and emissions at varying compression ratios of 18, 17.5 and 17. Readings such as speed, Mass flow rate and emissions were noted down.

4.1. Performance Parameters

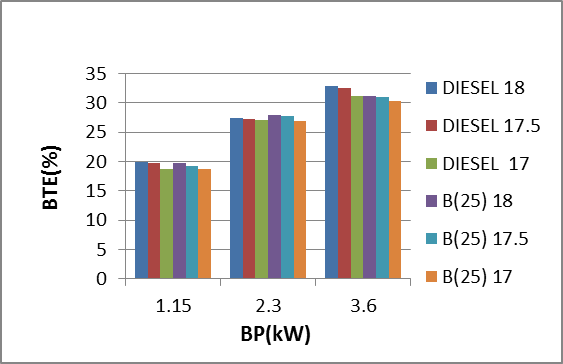

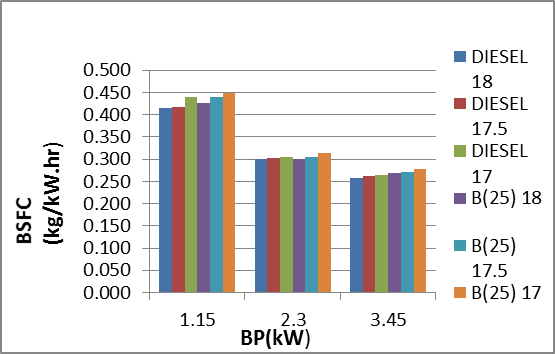

- BTE and BSFC are analyzed and represented graphically in Figure 1 and Figure 2.

| Figure 1. Variation of brake thermal efficiency with brake power |

| Figure 2. Variation of brake specific fuel consumption with brake power |

4.1.1. Brake Thermal Efficiency (BTE)

- It is observed from Figure 1 that the BTE increases with increase in BP. BTE of B25 are lower than diesel at all compression ratios, which is due to the lower calorific value of blend. At compression ratio 18, B25 shows 31.2% and diesel shows 31.9% of BTE for BP 3.6 kW. It is observed that as the compression ratio increases the BTE increases. This may be due to better combustion process. From compression ratio 17 to 18, the BTE of B25 has increased by 2.6% at maximum load.

4.1.2. Brake Specific Fuel Consumption (BSFC)

- It is observed that BSFC decreases with increase in BP from Figure 3. Diesel has lower BSFC than B25 at different compression ratios, this may be due to higher viscosity and lower calorific value. At compression ratio 18, the BSFC of B25 is lower than that of all other compression ratios and also the BSFC of B25 is close to straight diesel with 0.300 kg/kW.hr. At the lower sides of the compression ratios, the fuel consumption is high due to incomplete combustion of the fuel.

| Figure 3. Variation of hydro carbons with brake power |

4.2. Emission Characteristics

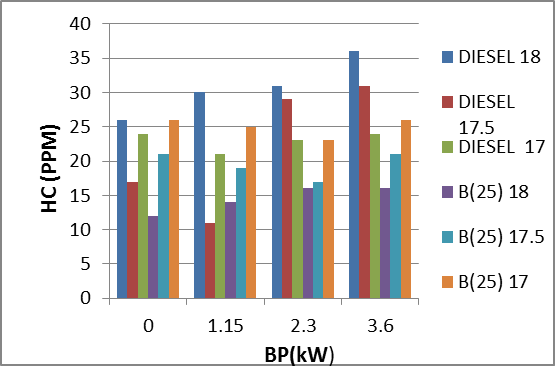

4.2.1. Hydro Carbon Emission (HC)

- The variation of hydrocarbon emission with different compression ratios for diesel and B25 is given in Figure 3. It is observed that for blend the hydrocarbon emission decreases with increase in compression ratio. At higher compression ratio the Figure 3 shows reduced hydrocarbon emission for B25 than diesel. This may be due to complete combustion.

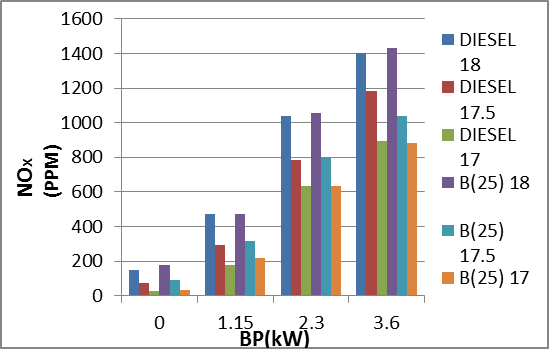

4.2.2. Nitrogen Oxide Emissions (NOx)

- The variations of nitrogen oxide emissions with respect to different compression ratios are shown in Figure 4. It is observed that with increasing load the NOx emission is increasing. This may be due to higher combustion temperature in the cylinder. The NOx emissions for diesel and blend increase with increase in compression ratio. At compression ratio 18 the blend shows higher NOx emissions than diesel for maximum BP because of higher temperature. From compression ratio 17 to 18, the NOx emissions of B25 has increased by 38%.

| Figure 4. Variation of nitrogen oxide with brake power |

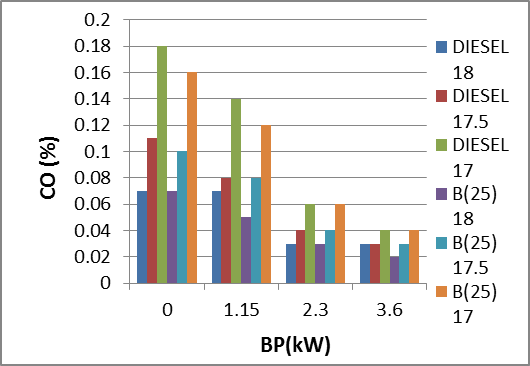

4.2.3. Carbon Monoxide Emission (CO)

- Figure 5 shows the variation of carbon monoxide emission of B25 and diesel with different compression ratios. The carbon monoxide emissions for diesel and blend decrease with increase in compression ratio. The carbon monoxide emission of blend is found to be close to the standard diesel for maximum BP. The decrease in CO emissions from compression ratio 17 to 18 is negligible.

| Figure 5. Variation of carbon monoxide with brake power |

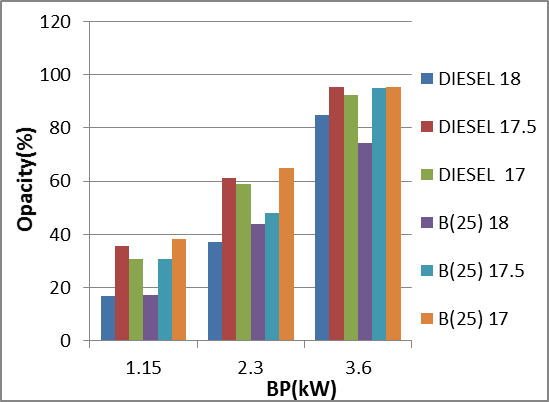

4.2.4. Smoke Opacity

- It is observed that smoke opacity increases with increase in load as shown in Figure 6. At compression ratio 18, B25 shows reduced smoke opacity than diesel when compared with other compression ratios, this may be due to better combustion at optimum compression ratio. From compression ratio 17 to 18, the Smoke Opacity of B25 has decreased by 27%.

| Figure 6. Variation of smoke opacity with brake power |

5. Conclusions

- The following conclusions may be drawn from the present study.• A higher compression ratio of 18 gives better BTE for B25. The B25 showed increased BSFC than diesel at different loading conditions. At compression ratio 18, the B25 showed close BSFC to the standard diesel than other compression ratios.• The nitrogen oxide emission of B25 is higher at compression ratio 18 which is almost close to diesel. Nitrogen oxide emission is increased with increase in compression ratio for both blend and diesel.• Carbon monoxide emission for diesel and B25 decrease with increase in compression ratio. Hydro carbon emission for B25 is decreased with increase in compression ratio and it is higher for diesel than blend at different compression ratios.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML