-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2015; 5(1A): 5-9

doi:10.5923/c.ep.201501.02

Effect of Compression Ratio on the Performance and Emission Characteristics of Blends of Lard Oil Methyl Ester and Diesel on C I Engine

Sunil J. D’Souza , Vinoothan Kaliveer , Sushanth H. G. , Rolvin S. D’Silva , K. Raju

Department of Mechanical Engineering, St Joseph Engineering College, Mangaluru, India

Correspondence to: K. Raju , Department of Mechanical Engineering, St Joseph Engineering College, Mangaluru, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

In the present study, Lard oil methyl ester (LOME) has been extracted from pig fats by base-catalyzed transesterification with methanol in the presence of sodium hydroxide (NaOH) as catalyst. The effect of LOME addition to pure diesel on the performance and emission characteristics of direct injection diesel engine has been experimentally investigated by varying the compression ratio at a constant load. The experimental test results showed that the addition of LOME to diesel decreased the brake thermal efficiency of the engine by 3% and increased the specific fuel consumption by 3% compared to pure diesel. But for B20 blend, carbon monoxide (CO), hydrocarbon (HC), oxides of nitrogen (NOx) and smoke emission are decreased by 20%, 4%, 14%, and 3% respectively as compared to pure diesel at full load of the engine.

Keywords: Lard Oil Methyl Ester, Diesel, C I Engine, Emission

Cite this paper: Sunil J. D’Souza , Vinoothan Kaliveer , Sushanth H. G. , Rolvin S. D’Silva , K. Raju , Effect of Compression Ratio on the Performance and Emission Characteristics of Blends of Lard Oil Methyl Ester and Diesel on C I Engine, Energy and Power, Vol. 5 No. 1A, 2015, pp. 5-9. doi: 10.5923/c.ep.201501.02.

Article Outline

1. Introduction

- The production and use of fossil fuel in internal combustion engines causes environmental pollution, such as rise in carbon dioxide levels in the atmosphere [1]. The combustion of petroleum leads to emission of CO, SO2, NOX etc resulting in global warming, which threaten wild and human life, impacts on the environment and human health. Hence research is going on to find an alternative for diesel fuel. Biodiesel is a liquid biofuel obtained by chemical processes from vegetable oils or animal fats and an alcohol that can be used in diesel engines alone or blended with diesel oil [2]. Different animal fats like pork lard, beef tallow, chicken fat, yellow grease and brown grease are used for biodiesel production [3]. Biodiesel is biodegradable and non-toxic and has low emission profiles as compared to petroleum diesel [4]. Hence biodiesel research has become more prominent research. Biodiesel can be obtained through the esterification process. During this process raw oil is tested for free fatty acid (FFA) content using titration method [5]. If FFA is less than 4% then directly transesterification can be carried out. If it is greater than 4%, more NaOH is added to covert oil to methyl ester. Esterification process is done by employing methanol/ethanol in presence of acid as homogeneous catalyst, among which H2SO4 exhibited very promising result [5].In transesterification reaction, NaOH and Methanol/ Ethanol are mixed in a conical flask till all the methanol/ Ethanol dissolves. Oil is heated in a round bottom three necked flask. Oil is heated up to the boiling point of Methanol/Ethanol. The mixture of methyl alcohol and NaOH is added to oil in the round bottom flask at that particular temperature. Heating is done for 2 hours and while heating mixture is continuously stirred by magnetic stirrer. Later this is transferred to a separating funnel and it is kept for one day for complete separation of biodiesel from glycerin. Then the methyl ester is separated from the conical flask and subjected to water washing. A small quantity of hot water is added and the biodiesel is water washed. This water washing is done till the mixture becomes clear. Heating the mixture will result in evaporation of water from the fuel sample. This end result is methyl ester which can be used as a fuel in IC engines.

2. Experimental Details

- In this work biodiesel is produced and its properties are measured. Experiments are conducted in VCR engine for different blends like diesel B10, B20 and B30 for performance and emission characteristics at three compression ratios at a constant speed of 1500 rpm.

2.1. Transesterification

- The biodiesel is produced by transesterification method which was carried out using a round bottom flask of 1 litre capacity, equipped with thermostat, mechanical stirrer, sampling outlet and condensation systems. A freshly prepared 300 ml methanol and 6.5 grams of sodium hydroxide solution are taken in a separate flask. 1000 ml of lard oil is heated to 65°C in the round bottom flask and the solution is mixed with the lard oil which is heated to 65°C. Now the reaction takes place for 2 hours with same temperature of 65°C. After 2 hours, the solution is taken in a separating funnel and kept for minimum 15 hours for proper settling of glycerin. The glycerin collected at the bottom of the funnel is taken out and lard oil methyl ester is washed with hot water to remove soap and glycerin content from the lard oil methyl ester till a clear lard oil methyl ester is obtained.

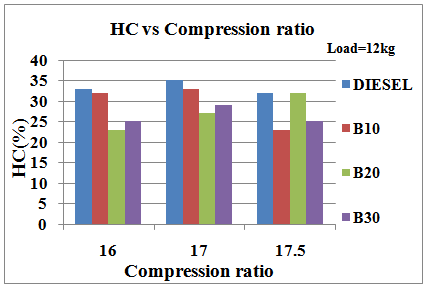

2.2. Properties of Fuel Samples (Diesel and Blends of LOME)

- Table 1 shows the properties of fuel samples. Higher Calorific value is found by Bomb calorimeter apparatus. Density is found by using hydrometer. Cannon Fenske Viscometer is used to measure the Kinematic Viscosity. Flash and fire points are found by using Cleveland open cup apparatus.

|

2.3. Engine Setup

- The Engine setup consists of a single cylinder, four stroke, water cooled variable compression ratio diesel engine connected to an eddy current type dynamometer for loading. A tilting cylinder block arrangement is used for varying the compression ratio without stopping the engine and without altering the combustion chamber geometry. Temperature sensor arrangements are made in the measurement of exhaust gas inlet and outlet temperatures, water jacket and calorimeter water. The exhaust gas emissions are measured using an exhaust gas analyser and smoke opacity is measured using a smoke meter.

3. Results and Discussion

- The experiments were conducted at a constant speed of 1500 rpm for three different compression ratios of 16, 17 and 17.5 at an injection pressure of 200 bar with diesel and LOME blends (B10, B20 and B30). Mass flow rate, load, emissions and smoke opacity readings were recorded for various loads. Engine performance parameters like brake thermal efficiency (BTE) and brake specific fuel consumption (BSFC) were calculated.

3.1. Performance Characteristics

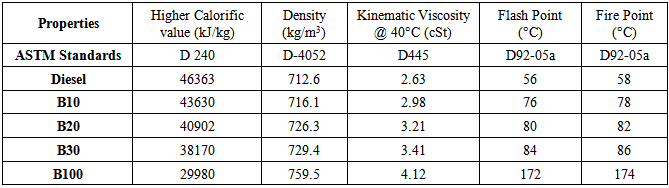

3.1.1. Brake Specific Fuel Consumption (BSFC)

- Figure 1 shows the variation of BSFC with respect to compression ratio for diesel and LOME blends (B10, B20 and B30) for 12 kg load. From the graph it is observed that, as compression ratio increases BSFC decreases. This is due to the reason that at higher compression ratio the power generated is high with respect to fuel consumption [6]. And also as the percentage of biodiesel in the blend increases, BSFC increases. It is due to the lower calorific value of biodiesel and its blends compared to diesel, more amount of fuel is required to produce the same power output [7]. Here among the three compression ratios, BSFC is minimum for a compression ratio of 17.5. Also as percentage of LOME in the blend increases BSFC also increases. From compression ratio 17 to 17.5 for diesel, BSFC decreases by 1%.

| Figure 1. Variation of BSFC with Compression ratio for different fuel samples |

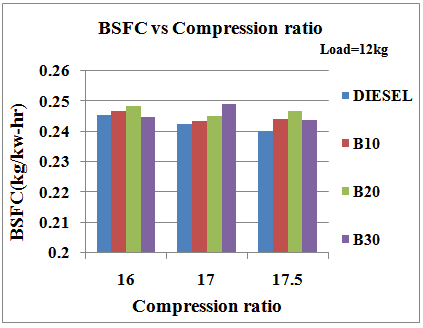

3.1.2. Brake Thermal Efficiency (BTE)

- Figure 2 indicates the variation of BTE with respect to compression ratio for diesel and LOME blends (B10, B20 and B30) at a load of 12 kg. It observed that as compression ratio increases BTE also increases. This is due to the increase in compression ratio ensures better air-fuel mixing and faster evaporation and leads to complete combustion [8]. But as biodiesel in blend increases, BTE decreases. This is due to combined effect of its lower heating value and increase in fuel consumption [9]. BTE is maximum at compression ratio 17.5. 2.4% increase in BTE is observed when compression ratio is increased from 17 to 17.5.

| Figure 2. Variation of BTE with Compression ratio for different fuel samples |

3.2. Emission Characteristics

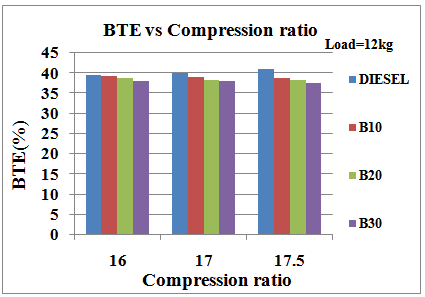

3.2.1. Hydro Carbon (HC)

- Figure 3 shows variation of HC with respect to compression ratio for diesel and LOME blends (B10, B20 and B30) at a load of 12 kg. It is observed that as compression ratio increases, emission of hydrocarbon decreases. This is due to the increase in air temperature at the end of compression stroke, enhancement in combustion temperature and reduction in charge dilution leads to complete combustion and reduction in hydrocarbon emissions [10]. And as percentage of biodiesel in blend increases, emission of HC also decreases. The HC emission is least at compression ratio 17.5 among the three compression ratios. For diesel fuel HC is decreased by 3.5% at a compression ratio of 17.5.

| Figure 3. Variation of HC with Compression ratio for different fuel samples |

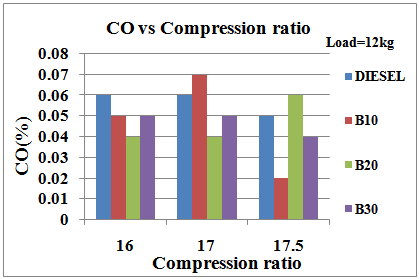

3.2.2. Carbon Monoxide (CO)

- The variation of CO with respect to compression ratio for diesel and LOME blends (B10, B20 and B30) at a load of 12 kg is shown in Figure 4. It is observed that as compression ratio increased, emission of CO is decreased. This is due to, at high compression ratio better combustion occurs [6]. Also as percentage of biodiesel in the blend increased, emission of CO is decreased. At a compression ratio of 17.5 the values of CO emission are a minimum among the three compression ratios.

| Figure 4. Variation of CO with Compression ratio for different fuel samples |

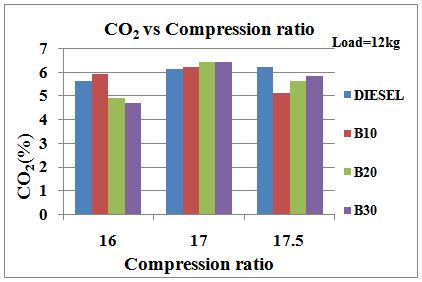

3.2.3. Carbon Dioxide (CO2)

- Figure 5 shows the variation of CO2 with respect to compression ratio for diesel and LOME blends (B10, B20 and B30) at a load of 12 kg. It is observed that as compression ratio increases, emission of CO2 decreases. This is due to the better combustion [6]. Also as percentage of biodiesel in blend increases, the carbon dioxide emission decreases. At a compression ratio of 17.5 for B10 fuel sample the CO2 emission decreases by 17.7% compared to the emission at a compression ratio of 17.

| Figure 5. Variation of CO2 with Compression ratio for different fuel samples |

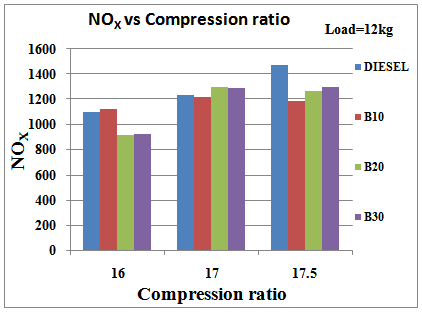

3.2.4. Oxides of Nitrogen (NOX)

- NOx is formed during combustion because of high temperature inside the cylinder. Figure 6 shows the variation of NOX with respect to compression ratio for diesel and LOME blends (B10, B20 and B30) at a load of 12 kg. It is observed that as compression ratio increases, emission of NOX also increases. Also as percentage of biodiesel in blend is increased, emission of NOX also increased. This is due to the availability of excess oxygen in the biodiesel. Hence highest NOX is observed at a compression ratio 17.5. For diesel NOX increases by 16.4% at a compression ratio of 17.5 compared to that at compression ratio of 17.

| Figure 6. Variation of NOX with Compression ratio for different fuel samples |

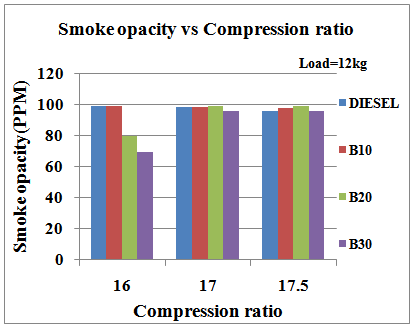

3.2.5. Smoke Opacity

- Figure 7 shows variation of smoke opacity with respect to compression ratio for diesel and LOME blends (B10, B20 and B30) at a load of 12 kg. It is observed that as compression ratio increases, smoke opacity decreases for most of the loads and the blends. But as percentage of biodiesel in blend increases smoke opacity also increases. At a compression ratio of 17.5 the emission of smoke will be less than that at other compression ratios. At a compression ratio of 17.5, smoke opacity value for B20 is decreased by 2.5% as compared to that obtained at a compression ratio of 17.

| Figure 7. Variation of Smoke opacity with Compression ratio for different fuel samples |

4. Conclusions

- The following conclusions may be drawn from the present study.• The performance and emission characteristics are better for LOME blends at a compression ratio of 17.5.• As the compression ratio increases the BTE increases but BSFC decreases.• As the percentage of LOME in the blend increases, BSFC increases but BTE decreases.• As compression ratio increases, emissions of HC, CO, CO2 and smoke opacity decrease but NOX increases. • As the percentage of LOME in blend increases, emissions of HC, CO and CO2 decrease but NOX and smoke opacity increase.

ACKNOWLEDGEMENTS

- The authors are grateful to the Management, NMAMIT, Nitte, for the facilities provided for the preparation of biodiesel. Also the authors are thankful to the Management, St. Joseph Engineering College, Mangaluru, for providing the facilities for conducting the performance and emission testing.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML