-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Economics

p-ISSN: 2166-4951 e-ISSN: 2166-496X

2013; 3(C): 100-107

doi:10.5923/c.economics.201301.17

Implementation Framework for Design-To-Cost Using TRIZ: Product Concept Design in Automotive Stamping Process

Zulhasni Abdul Rahim1, Nooh Abu Bakar2

1Razak School, Universiti Teknologi Malaysia, Kuala Lumpur, 54100, Malaysia

2Malaysia Japan Institute of Innovation and Technology, Universiti Teknologi Malaysia, Kuala Lumpur, 54100, Malaysia

Correspondence to: Zulhasni Abdul Rahim, Razak School, Universiti Teknologi Malaysia, Kuala Lumpur, 54100, Malaysia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The purpose of the research carried out was to identify ways in which tools and methodologies from Theory of Inventive Problem-Solving (TRIZ) to solving gaps within the Design-To-Cost (DTC) strategy in product concept development. The aim was to develop an implementation framework for DTC improving product cost and at the same time increase the product innovation. The research paper review the TRIZ methodology that have the potential for cost reduction, followed by a discussion of the DTC strategies that commonly practice in the various industries. The proposed new DTC implementation framework with TRIZ tools is establish and the research paper concludes with a case study using the new framework.

Keywords: Design To Cost, Theory of Inventive Problem-Solving, TRIZ, Automotive, Product Management

Cite this paper: Zulhasni Abdul Rahim, Nooh Abu Bakar, Implementation Framework for Design-To-Cost Using TRIZ: Product Concept Design in Automotive Stamping Process, American Journal of Economics, Vol. 3 No. C, 2013, pp. 100-107. doi: 10.5923/c.economics.201301.17.

Article Outline

1. Introduction

- The challenges in automotive industries are increasing rapidly. Today’s market liberalization and global competition have pushed most of the companies to change the way they run the business. This becomes the key survival for the companies to have sustainable business model. As for automotive companies to sell their product, it is very crucial that the product able to meet the customer requirement and give the satisfaction that they need. However, these companies have to struggle with the product development with critical constraint of time-to-market and most importantly the investment cost, this are normally the main risk in product development project. Therefore, to meet both ends as the ideal results[1], to full fill customer requirement in the product and function they want to buy and producing product on time, without exceeding the investment budget allocated to the project is very challenging[2]. Furthermore, to strive towards cost saving throughout the product development project is not recommended because it will have major impact to the main project goals.The ultimate goal of DTC is have to design and produce new valuable products within the price range of which customers would buy it. In definition, DTC is a method of ‘Management by Objective’ which uses the information of difference with referring to the allocated unit production cost in each design work breakdown structure and approaches to the result by step by step design[3]. However, in real situation, a lot of product development project have been dragged backward or delayed the time-to-market, this give huge negative impact to the organization goals. Furthermore, some DTC ideas have contradiction parameters between low-cost product design and quality performances, traditionally trade-off has been used to get the balance between both conflicting requirements and accepted as the solution to the design. The trade-off analysis will provide solution that needs an amount of sacrifice in customer satisfaction to achieve a certain amount of cost saving, this will negatively impact the product competitive performance and also product innovation. Adopting DTC is full of great challenges, there is evidence that shows DTC implementations are often giving negative impact and failed to perform in product development application and processes. This paper presents a validation process of the proposed DTC implementation framework using TRIZ tools. The purpose of framework validation is to identify whether the application of TRIZ tools in implementing DTC for product concept design and development bring better outcome without any trade-off required to resolve conflicting parameters. This paper start with literature review focusing on DTC implementation, the proposed framework and framework validation. The research method section has described in detailed on TRIZ tools and processes. Then, the results of validation process are explained in the result and discussion section. Finally, the final DTC implementation framework is presented

2. Literature Review

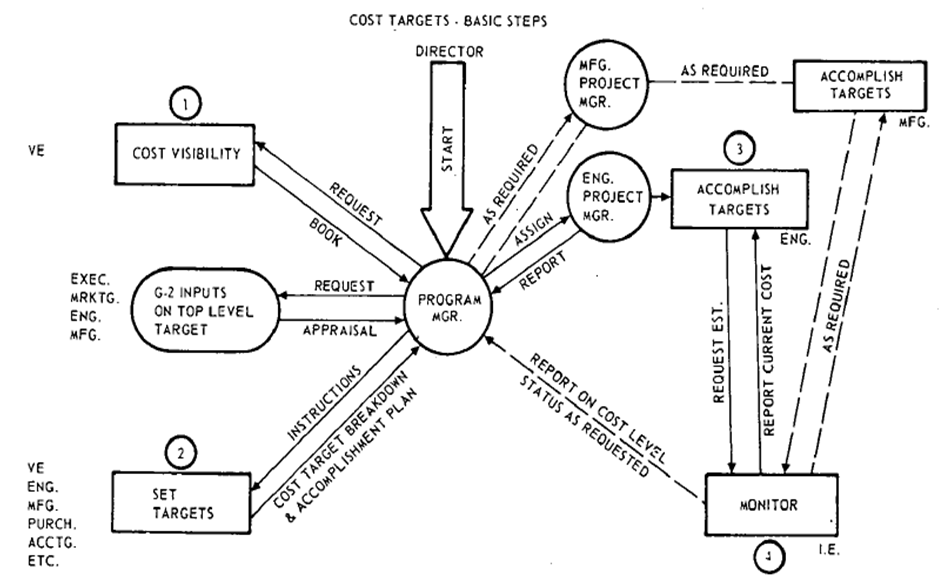

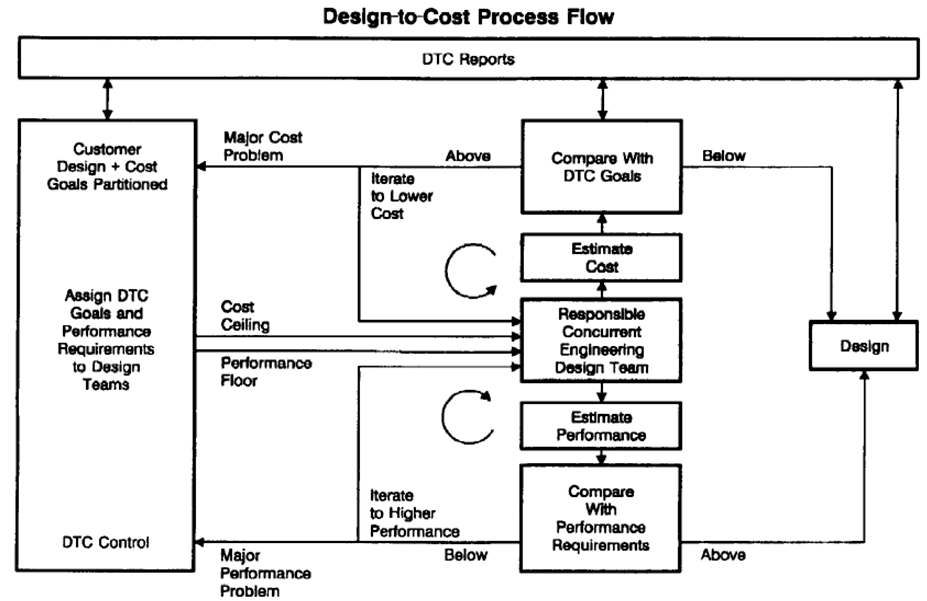

- Facing today's turbulent market environment, companies are compelled to rethink sequential planning procedures with the objective to integrate and synchronize the product design, process planning and cost estimating activities. Product modifications and process alterations are the more expensive the later they occur in the development cycle. The objective of concurrent cost information is to optimize the product design with respect to balancing the trade-off between cost and performance requirements before prototype build. The identification of cost and performance sensitive parameters to forecast the system's competitiveness is still to be developed. Furthermore, the need for cost reduction is growing as more companies struggle with global competition and the faltering economy. One way that companies can regain control over their costs is not only to assess these costs, but also systematically classify and identify product costs. Using a systematic approach to perform cost reduction not only yields cost improvement but provides decision-makers with the trade-offs involved in achieving these reductions[4].There are several strength and weaknesses in the DTC strategy that support product concept design. The strength of DTC the capability to define a measurable design parameters and can be evaluated with performance, provide the communication bridge between designers and other to improve product cost, the capability to improve total cost including product and the processes and focusing on idea generation to improve product cost. However the DTC weaknesses are the gaps to achieve effective product cost improve goals, such as using trade-off to quickly solve any issue of unmet target cost, low innovation in product design, not improving deficiencies in critical angle or any harmful functions, indirect implication such as delaying the project time-to-market and impact the development cost[5]. The application of Design-to-cost started in the military and aviation sector later expand to non military sector and industries, including case studies using target costing and design to cost is the automotive industries[6-9]. Adopting Design-to-cost and target costing is significant to the automotive industry due to the level of product complexity that needs to be managed, this similar with the aeronautic and aviation industries. The needs for the automotive industry to adopt this strategy is because the pressure from market globalization that happen nowadays. Most of the countries participate in the Free trade agreement with an objective to improve economic performance, especially for developing countries. For the local and international manufacturer, it becomes an opportunity to expand the operation and securing the market percentage. This situation create competitive environment for the manufacturer to increase their market sales and generating higher profit by producing low product cost with better quality[10]. In a manufacturing environment, the strategy of Design-to-cost start from the calculation of product costs has traditionally been the domain of industrial engineering and cost accounting where the role of industrial engineering was to evaluate the cost of the product after design and the role of cost accounting was to provide control and cost information to management regarding execution of the product design. Currently the tools used to generate ideas to support DTC are limited and not systematically structured in problem solving process[11].According to Steinmetz[12] to gain effectiveness in implementing DTC is by early involvement of product and concept design, therefore a clear direction and procedure are required to successfully implement. Figure 1 shows a framework for the implementation of DTC in product design and development. The author proposed that the framework need to have operating procedure in phases. The DTC implementation framework consists of 4 main phases which communicated with the program manager.Similar point highlighted by Williamson[13] in Figure 2, that DTC need to start as early as possible in order to identify the opportunity to make improvement easier and maximize the cost reduction and other benefit. A DTC framework is developed for electronic companies, which focus on developing design for DTC and its processes that contribute to achieve the goals. The cost reduction tools for the framework is trade study, where the author found that the tool have limitation in commitment in reducing cost. Therefore, the need for tools that able to overcome the weaknesses in trade analysis is significant. By using TRIZ tools in DTC, it is expected to give better result in cost reduction goals.

| Figure 1. Design To Cost Framework by Steinmetz[12] |

| Figure 2. Design To Cost process flow by Williamson[13] |

3. Integration of TRIZ into Design-To-Cost Strategy

- TRIZ comes from the Russian phrase “teorija rezhenija izobretatelskih zadach”, which means the “theory of inventive problem solving”. It was developed by Genrich Altshuller (a Russian scientist and engineer, 1926-1998), who studied about 400,000 technology patents1, and from them drew out certain regularities and basic patterns which governed the process of solving problems, creating new ideas and innovation. This provided an understanding for the creation of a systematic process for invention of new systems and the refinement of existing ones[14].As to implement the concept of Design-to-cost in the product design, Trade studies are essentially decision- making exercises. It means that determining the effect of decreasing one or more key factors and simultaneously increasing one or more other key factors in a decision, design, or project. Some analytical tools applied were unable to secure the issue of uncertainty in decision making process. Therefore it can be conclude that the need of new approach is critical in decision-making activities, which eliminate the dependability of trade-off concept.Contradiction is the ultimate reason that trade-off is chosen. Is almost the complete opposite of traditional problem solving strategies such as trade-off, in which the emphasis is very firmly placed on the importance of achieving ‘optimum’ compromises between conflicting problem parameters. The keen emphasis on ‘trade-off’ solutions in traditional problem solving practice often means that designers are rarely explicitly aware that conflicts exist. The first major part of the paradigm shift that takes place in the Contradictions part of Theory of Inventive Problems Solving (TRIZ) is the need for problem solvers to actively seek out the conflicts and contradictions inherent in all systems. The second part then involves using the TRIZ methodology to try and ‘eliminate’ those contradictions rather than to accept them. By solving contradiction and strive towards Ideality without any trade-off, regard of any changes occur in product development process. Therefore, TRIZ have the capability to provide the opportunity to complement the significant weakness in adopting Design-to-cost concept in product design, even though there are constraints for TRIZ tools be used in cost improvement activities[15]. There is a time/cost trade off or contradiction for innovation, in which development time is shortened but the development cost is increased. The core of innovation is to find difficult problems, such as the problems with contradictions, and to solve them quickly. TRIZ is expected to perform in providing a solution for the restriction of innovation and technology improvement experienced in implementing Design-to-cost in product design and development, such as upgrading value of design[16]. The idea development is supported by principles, effects and standard solutions. Design integration of configuration and manufacture are supported by environment, but if there is any contradictions the principles of TRIZ can be used. Under the application of Design-to-cost, the designers with some knowledge of TRIZ of a company will increase the speed of product development and reduce the cost at same time.While undoubtedly powerful, TRIZ is not yet comprehensive enough to tackle all types of problems. The method has begun to be integrated with a number of established and emerging problem definition and problem solving tools and strategies. This integration of TRIZ have been achieved with other concepts such as Quality Function Deployment (QFD), Failure Mode Effect Analysis (FMEA), Value stream Mapping (VSM), Value Engineering (VE), Theory of Constraint (TOC),Taguchi, Design For Manufacturing Assembly (DFMA), Six Sigma and other established new integration concept[17]. The complementary area from the integrating TRIZ is identified in five basic problems type. They are problems in which a new function is sought, problems in which we wish to improve some aspect of an existing system, problems where we wish to make a step change evolutionary improvement to an existing system, problems which relate to reliability-type issues, problems which relate to mature systems in which there are cost reduction type drivers such as End-Of-Life cycle[18]. Therefore, the evidence shows that there is high possibility to integrate TRIZ with Design-to-cost strategy. TRIZ is the most comprehensive systematic innovation and creativity method known. It offers a generic problem-solving framework into which other tools have already begun to be successfully integrated.Based from the literatures, the main TRIZ tools that suitable for DTC are product & component analysis, function analysis and trimming[19-22]. Then from the trimming activity, a problem is normally created to solve function problem or contradiction problems between parameters. The DTC ideas that generated from TRIZ tools need to be review and evaluated. In evaluation phase the idea will be rated based from two contradicted criteria, ‘Ease of implementation’ and ‘High potential cost saving’. Using the Contradiction Matrix, both parameters that associated with the criteria provide general solution to solve those contradictions.The gap in the research is concluded as there is lacking in the innovative solution for Design-To-Cost Strategy , this can be solve by integrating specific TRIZ tools in the implementation framework that able to provide better results not just in reducing cost but also improve product innovation.

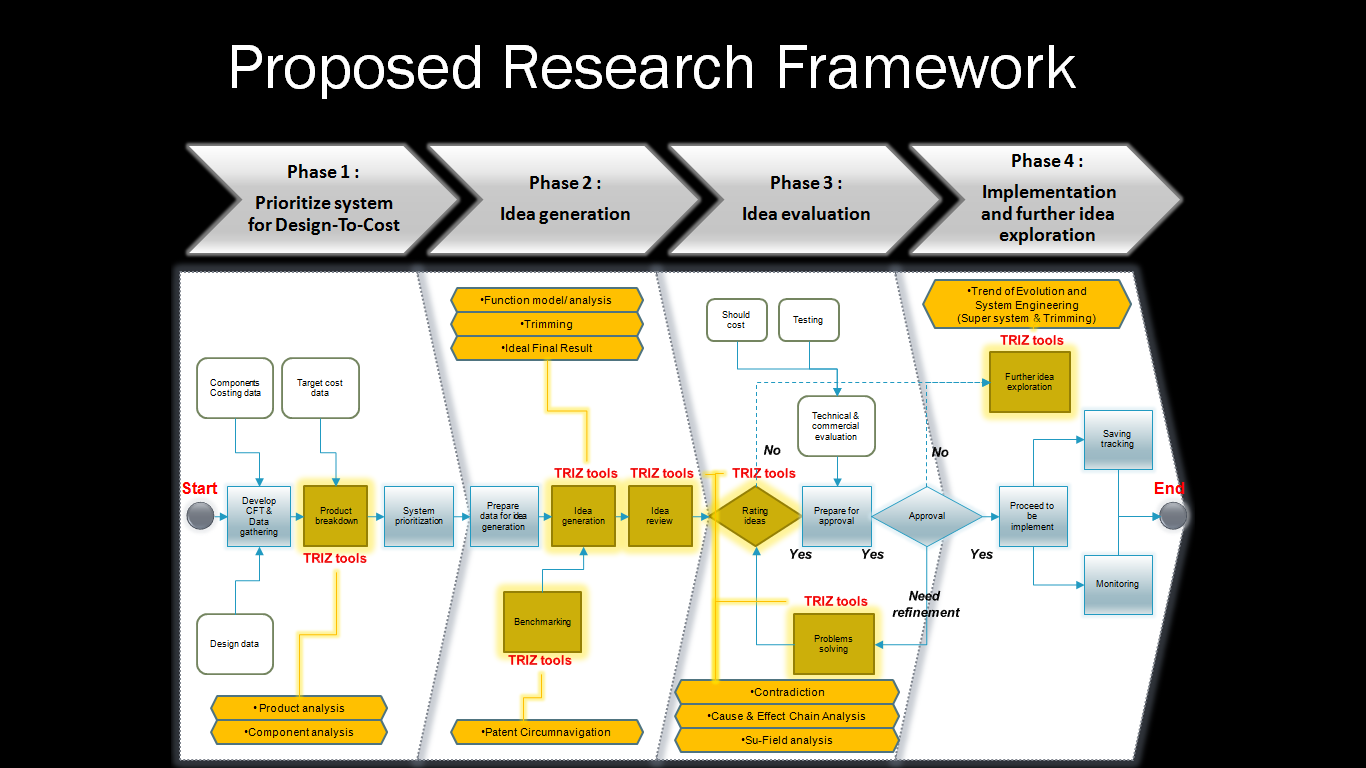

4. Implementation Framework of Design-To-Cost for Product Concept Design Stage Using TRIZ Tools

- A framework for DTC implementation is developed by the author through literatures and multiple case studies highlighted in previous section. The proposed framework as shown below is a part of product design and development process. The DTC implementation process is conducted in main four phases, first phase is prioritization of DTC system, second phase is idea generation, third phase is idea evaluation and the fourth phase is the implementation ideas and Off-line idea exploration. Figure 3 shows the proposed implementation framework of DTC phases consist of main activities and TRIZ tools that need to be used in the processes. Before initiate the DTC in product development, the most important data established is the target cost, this will be the foundation of overall DTC deliverables and goals. Starting with the first phase, the product concept designs are analysed through product analysis and components analysis.

| Figure 3. Proposed Design To Cost Framework with TRIZ |

5. Case Study

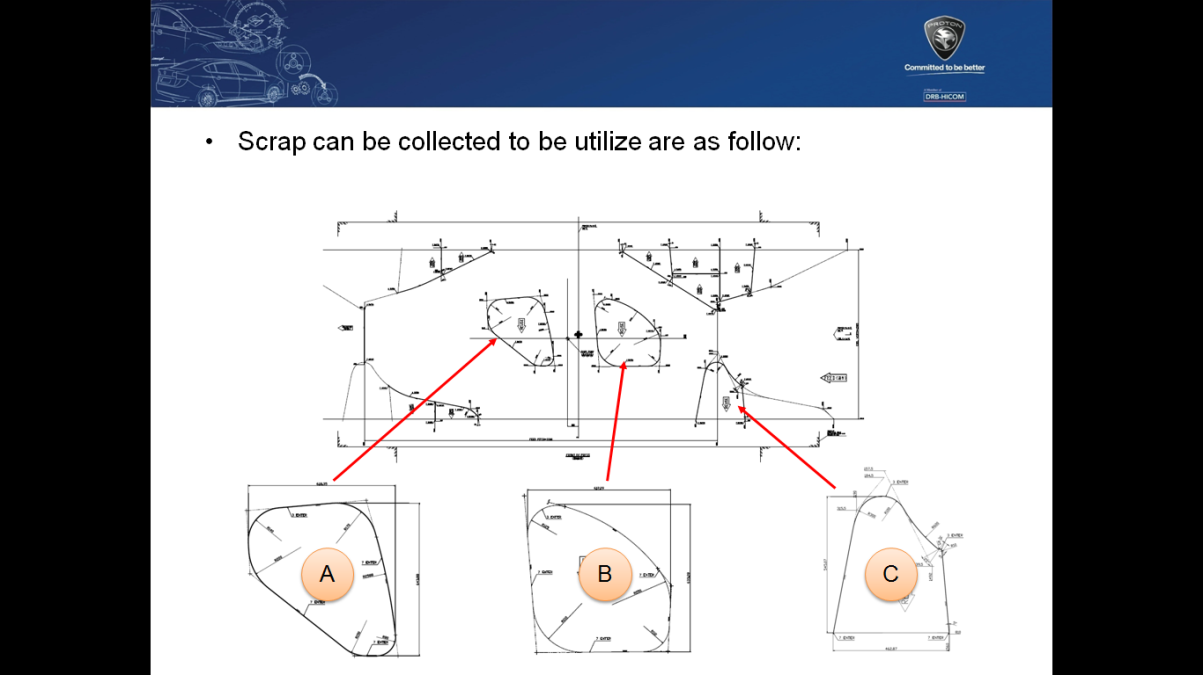

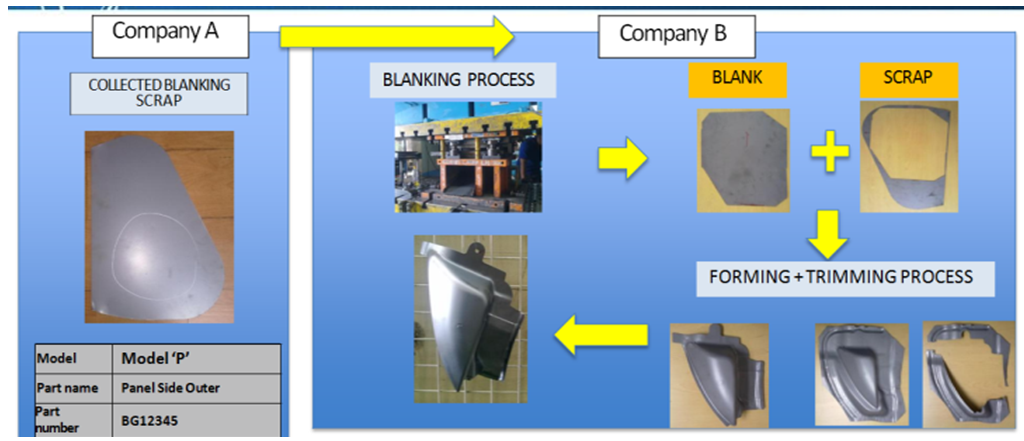

- In the automotive industries, the usage of material is critical to the product design. The design will determine the sufficient amount of required material for a specific design. This case study selected sheet metal as the focus for the DTC project. This selection is base on the material cost and the quantity usage to manufacture a component based from metal sheet. The process of producing component from sheet metal require a lot of energy and resources such as large stamping machine and high logistic activities from process to another with more than 200 metal part with various type of size weight and also many level of assemblies process.Therefore DTC need to design metal parts with better productivity and maximize the utilization of sheet metal area to produce stamping parts. This highlighted the engineering contradiction parameters between’ Productivity’ and ‘Area of stationary object’. Based from level of problem, the idea generation activity utilized contradiction matrix to generated solution for this DTC activity. There are four solutions shows from the contradiction matrix, 7- Nesting, 10-Prior Action, 15-Dynamicity/ Optimization & 17- Moving to a new dimension.Assessing on engineering perspective, the current design of blank sheet metal of pane side outer, there is possibility that the concept of 7-Nesting is applicable for this DTC activity. Figure 4 show that the blank sheet design can incorporate other blanking sheet for other parts. Based from type of material and sizes of the blank sheet metal, the engineering found there are similar components that have using same type of material or lower grade but most importantly the components must have the same material thickness, as show in Figure 4. The idea is feasible to be implement into the concept design of panel side outer blanking sheet metal, this provide the opportunity to the engineers to expedite the concept into the product design.Concurrently, the cost strategies of DTC also look into the feasibility of cost impact to product cost. The parameters of cost improvement in productivity, material usage, energy consumptions, logistic cost, and manpower cost against the investment cost in providing tooling to the engineers to implement the proposed ideas. From the cost analysis done by the procurement engineers, the return of investment are positive, the estimated data highlighted that the return of investment is within two months subjected to volume.From both analysis of engineering and costing, the idea is justified and proceed for implementation. The balance sheet metal from the stamping process of panel side outer, owned by company A, will send to company B, C and D with invested tooling of stamping die to stamp other smaller stamping components, as show in Figure5.

| Figure 4. Design concept of reusable material |

| Figure 5. Implementation of TRIZ solution for reusable material |

6. Conclusions

- The aim of this study was to validate a proposed framework of DTC implementation with TRIZ tools application. A case study method was used to find out whether the DTC implementation with TRIZ tools could provide successful cost reduction in product costing. With a case study presented, the results were positive. One of the main contributions is by introducing TRIZ tools in DTC, the idea generated have managed to solve contradiction parameters that constraint the exploration of potential cost saving in a product design and development. The most critical TRIZ tools that able to enhance the potential of cost reduction in product design are function analysis and trimming. The authors believe that the cost reduction can be increase and also develop product to higher level of innovation.It should be acknowledged that the case studies used in this study has some limitation. The TRIZ applications in the stamping case study using contradiction matrix that suit the problems. The established solutions provide guidelines for future product development and concept design, shows that the DTC become more effective and more product innovation. Therefore, in future research, the final framework will be tested and applied in other type of industries or different field in order to further refine and eliminate any weakness that the framework might have.

ACKNOWLEDGEMENTS

- The authors wish to acknowledge all the contributors, especially Universiti Teknologi Malaysia for giving opportunity and support to carry out research successfully.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML