-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Economics

p-ISSN: 2166-4951 e-ISSN: 2166-496X

2013; 3(C): 47-51

doi:10.5923/c.economics.201301.09

Mediating Effect of Operational Cooperation between Supply Chain Practices and Firm Performance

Thoo Ai Chin1, Abu Bakar Abdul Hamid1, Amran Rasli1, Nik Muhammad Naziman Abd Rahman2

1Department of Management, Universiti Teknologi Malaysia, Johor, 81310, Malaysia

2Faculty of Business Management, Universiti Teknologi MARA, Kelantan, Kota Bharu, 15050, Malaysia

Correspondence to: Thoo Ai Chin, Department of Management, Universiti Teknologi Malaysia, Johor, 81310, Malaysia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Operational cooperation (OC) has enhanced the ability of firms to cope with uncertainty and stiff competition through supply chain collaboration. In this study, previous supply chain frameworks are extended to include OC as a mediator in the relationship between supply chain practices (SCPs) and firm performance (FP). Responses from 201 small manufacturing firms and structural equation modeling were used to test the proposed structural model. The data showed that the relationship between SCPs and FP is mediated by OC. The findings are particularly important for small manufacturers owing to resource paucity and the need to collectively draw upon both SCPs and OC in order to ensure a sustainable FP.

Keywords: Supply Chain Practices, Operational Cooperation, Firm Performance

Cite this paper: Thoo Ai Chin, Abu Bakar Abdul Hamid, Amran Rasli, Nik Muhammad Naziman Abd Rahman, Mediating Effect of Operational Cooperation between Supply Chain Practices and Firm Performance, American Journal of Economics, Vol. 3 No. C, 2013, pp. 47-51. doi: 10.5923/c.economics.201301.09.

Article Outline

1. Introduction

- Survival and growth of manufacturing industry can be difficult in current competitive business environment and global marketplace; customers are more demanding to have better and cheaper products, higher service levels, more product varieties and faster delivery[1-2]. It can be a real challenge to deliver a right product at the right place at the right time with the right cost[3-4]. These challenges stress the importance of managing cross-boundary relationships between business partners.Supply chain is a network consists of all parties involved directly or indirectly which includes manufacturer, supplier, retailer, customer and so forth, in producing and delivering products or services to ultimate customers – both upstream and downstream sides of supply chain through physical distribution, flow of information and finances[5]. Supply chain practices (SCPs) include a set of approaches and activities utilized by a firm to effectively integrate supply and demand for improving the management of its supply chain[4],[6-7]. SCPs are multi-dimensional concepts and can be measured from different perspectives. Different dimensions of SCPs have been highlighted in past literatures[7]. In this study, SCPs target only three practices: supplier selection and evaluation, supplier management and customer relationship. These practices are important to focus on interactive relationships development between company and its suppliers and customers. Capability is a superior and distinctive way of coordinating, deploying and allocating resources; it is different from a resource[8]. Operational cooperation (OC) is the ability to coordinate all related parties to work together as a whole to exchange information and develop a shared definition of the solution needed[9]. Information sharing is acted as an antecedent of dynamic trust and cooperation intention in supply chain[10]. The resource adversity or uncertainty may enhance cooperation. The uncertainty can be reduced through OC since this capability aids the development of a shared vision and deal with environmental uncertainty to obtain required information, exchange opinion, interpret task environment, resolve inter organizational conflicts and reach a shared task[11]. SCPs and OC continue to play critical roles in influencing firm’s ability to compete in market. Therefore, more and more studies are increasingly looking across the supply chain, beyond its encompassing concept, to establish a link between operations and supply chain management (SCM)[4],[12-13], with aim to create a seamless flow of goods/services and information from supplier, operations to ultimate customer. However, the linkages of SCPs and OC have not yet been addressed explicitly and modeled collectively in respect to their contribution to firm performance. Indeed, previous studies have found there is a linkage of SCPs and firm performance[1],[4],[14-17]. But inconsistent results are found on the direct relationship between SCPs and firm performance in companies of varied sizes. The implementation of SCPs has significant impacts on operational efficiency[7]. This implies that the actual contribution of SCPs to firm performance many not be direct; perhaps it is probably mediated by a number of competencies and interrelated objectives[18]. Given that firm capability is a significant source of greatest value and superior firm performance[19], it is vital to consider the impact of OC on firm performance.The main ambition of this study is to advance the theories of resource-based view (RBV), system and network perspective within SCM by developing a model linking SCPs, OC and firm performance. The theory of RBV emphasizes on how non-substitutable, inimitable, path dependent abilities a firm has developed over time, combined with other assets and become firms’ resources and contributed to their sustainable competitive advantage[20]. Besides, system theory aims to promote an integrated supply chain and affirm that the analysis level is determined by the integration capability of a firm[21]. Further, the network perspective focuses on inter-organizational interactions of several parties. Through coordination efforts and strategies, network can enhance resources competencies and capabilities of individual firm[21]. Enterprise competitive capability can be promoted if there is an internal decision and activity between firms and their external partners[22]. Though many SCM studies had been done on developed countries, limited research, particularly in Malaysia had been focused to test the effect of OC on SCPs and firm performance. In contrast to most of the previous studies, this paper recognizes the importance of capability in cooperation as RBV suggests that firms can pursue sustainable business performance if they possess rare, valuable, non-substitutable, inimitable and path dependent OC capability. Therefore, this paper proposes OC as a firm-specific capability that is hard to imitate and dependent by developing an integrative model to test the mediating effect of OC on SCPs and firm performance in manufacturing industry of Malaysian small and medium enterprises.

2. Conceptual Model

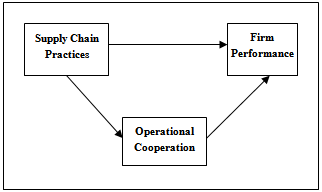

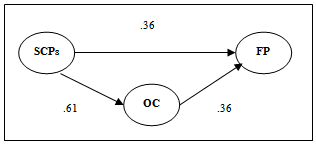

- The model linking the variables of SCPs, OC and firm performance is presented in Figure 1. The model is developed using earlier research in SCM, strategic management and operation management as theoretical foundations. The proposed theoretical construct of SCPs include supplier selection and evaluation (SSE), supplier management (SM) and customer relationship (CR). OC consists of information system and formal procedures to facilitate cooperation as well as employees are skilled at maintaining healthy relationships to solve problems. The firm performance is categorized into two forms: financial performance and operational performance. The financial performance is suggested to include cost and profit. The operational performance is measured by quality, delivery dependability, time to market, customer satisfaction and customer service responsiveness. The performance metrics are perceptual measures derived from respondents’ perceived performance relative to their competitors[14],[17]. Finally, it is imperative to note that the proposed constructs are not a complete set of measurement scale due to the entire of SCPs and firm performance can not be encompassed in just a single study.

| Figure 1. Conceptual model |

3. Hypothesis Development

- Practices are insufficient to drive better performance and improve profits, since the effects of competitors imitating a successful practice are not addressed inpractice-performance relationship[20]. Therefore, customized and proprietary practices are essential to keep firms’ competitive edge over their rivals. Firms face difficulty to achieve a sustainable competitive advantage if they adopt the same practices; long-term benefits are not guaranteed if generic practices can be easily copied. This claim provides broad framework for arguing the importance of relating SCPs and OC in explaining performance. In this study, the argument is that if firms utilize SCPs to drive OC and business performance, then competitors are not able to duplicate the strategies. This is mainly because the strategies can generate causal ambiguity and therefore they are impossible to replicate. Causal ambiguity will be a main barrier to imitation if the resource is applicable to knowledge-based or socially complex[23-24]. OC is a form of capability embedded in organizational processes and it revolves around transformation, learning and coordination[25]. The capability evolves from problems an organization faces over time through fitting practices with its unique history[26] and configuring resources in respond to its environment[8]. Capability is taken as a mechanism for transforming homogeneous practices into heterogeneous ways of deploying resources through a customization process: practices are adjusted to reflect firm’s history[26] and culture; encapsulated both explicit elements and tacit elements to handle the problems of firm[27]. Capability can coordinate practices to create unique, firm-specific interactions and complementarities[28]. Due to SCPs do not possess the necessary traits to be a source of competitive advantage (easy to substitute and imitable), there appears a means of nurturing the OC as a source of competitive advantage. As such, organizations must be able to simultaneously increase efficiency through SCPs and be innovative through OC. OC is hard to be identified, articulated and decoded once it is established and will have a long-term effect on performance. Therefore, OC generates a strong mediation effect between SCPs and firm performance. Accordingly, the following hypothesis is developed:H1: Operational cooperation mediates the relationship between supply chain practices and firm performance.

4. Sample, Data Collection and Measurements

- This study utilized a questionnaire consisting of 23 items to examine the hypothesis. The sample of Malaysian small manufacturing companies was drawn from Federation of Malaysian Manufacturers Directory (FMM) and list of companies from SMECorp Malaysia official website. The questionnaire was mailed and hand delivered to the firms from May 2012 to October 2012 and the title of the targeted respondent sought was primarily Chief of Executive, Managing Director, owner of the firm or senior officer/executive in charge of supply chain practices in the firm. The results indicated that majority of the respondents were senior management from the firms. The final usable sample, including both the mail and hand delivery survey, was 201. A non-response bias was conducted to compare the responses of early and late waves of returned surveys based on that late-respondents are considered as a sample of non-respondents and they are theorized to have similarities with non-respondents. The responses were also split as mail and hand delivery surveys; early and late respondents within the mail survey; and early and late respondents within the hand delivery survey. The non-response bias compared responders and non-responders, and mail and hand delivery surveys according to demographic variables such as job title, company ownership, sub sector, year of company establishment and company size. Chi-square test yielded no statistically significant differences between early-respondents and late-respondents, mail and hand delivery surveys, early and late mail responses, and early and late hand delivery responses, concluding that non-response bias was found in the study. The indicators in the proposed questionnaire were based on existing literature. In total, 13 questions were used to measure the construct of SCPs: (a) supplier selection and evaluation (SSE); (b) supplier management (SM); (c) customer relationship (CR)[4],[18]. The construct of OC was operationalized by indicators to reflect the extent to which firms emphasize information system and formal procedures to maintain healthy relationships with each other to diagnose/solve problems[27],[29]. For the firm performance, seven questions were used to measure operational and financial performance. Responses to the questions were based on a five-point Likert scale that ranged from 1 (strongly disagree) to 5 (strongly agree).

5. Data Analysis and Research Findings

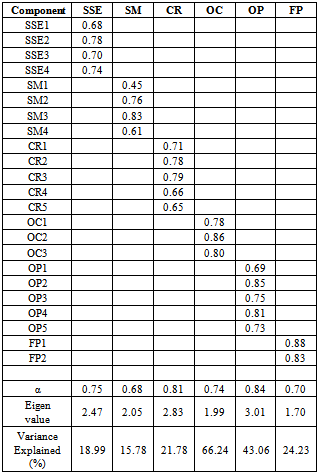

- Exploratory factor analysis (EFA) using principal component analysis with varimax rotation was used to assess construct validity of SCPs, OC and firm performance. The Kaiser-Meyer-Olkin (KMO) measure of sampling adequacy was computed to examine the appropriateness of factor analysis. Accordingly, a KMO value of 0.6 is acceptable and the Bartlett’s test should be significant at significance value of less than 0.05[30]. From the results, KMO values are well above the recommended acceptable level of 0.6; thus confirming that the collected data were worth to conduct a factor analysis. Table 1 shows that the factor loadings on all six constructs exceed 0.4[31], which exhibits sufficient validity for the measured items. In addition, the reliability of each factor was tested using Cronbach’s alpha (α) and the Cronbach alpha values between 0.6 and 0.7 are acceptable [32]. All factors were acceptable and indicated evidence of reliability as the Cronbach’s alpha values ranged from 0.68 to 0.84.

|

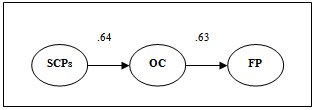

| Figure 2. Full mediation model |

| Figure 3. Partial mediation model |

6. Discussion and Conclusions

- This study adds to the existing literature by demonstrating that OC appears to mediate the relationship between SCPs and firm performance. The findings of the study indicate that all three SCPs including supplier selection and evaluation, supplier management and customer relationship demonstrated a significant positive effect on OC. Customer relationship was a strong indicator of SCPs compared to the other two dimensions. Consequently, firm performance can be enhanced by increasing OC. The result is consistent with previous studies which reveal that the link between SCPs and business performance is mediated by a number of competencies and interrelated objectives[7],[18],[27].This study provides additional insights for the management when implementing SCPs in their firms. The findings indicate that OC is a key intervening variable linking the variables of SCPs and firm performance. This investigation documents how SCPs contribute to prolonged firm performance through enhanced OC. Such research findings are imperative to organizations when they plan to adopt SCM implementation and also to the organizations that practice certain supply chain strategy, they could apply proposed strategies in this study with aim to improve continually their competitive edge. From the perspective of theoretical contribution, this study extends previous SCM frameworks in Western countries and advances the understanding between the relationship of SCM implementation, OC and organizational performance in Malaysian small manufacturing industry. In addition, a new relationship (SCPs, OC and firm performance) is proposed through landmark theories of RBV, system and network perspectives. This study implies some limitations and scarcity. First, the sample population of this study is based on small manufacturing firms in Malaysia. Having drawn from a list of FMM members and SMECorp, the results of this study are only generalizable to firms in that population. Though the sample of this study covered a wide range of industry groups, logic suggests that future research may need to include more geographical data coverage. It is of great importance to include more manufacturing companies in future research. The result would be much better if it can represent a full picture of Malaysia’s manufacturing industry. Second, the scope of generalizability of the results can be expanded if a broader population of firms such as large manufacturing industry is included in future research. Third, future research may need to include other variables such as leadership practices, quality management, integrated product development, just-in-time flow, logistics and workforce development that may have an effect on OC. Similarly, other mediating variables such as operational responsiveness, operational improvement, operational customization and operational reconfiguration may have an effect on organizational performance.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML