-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

American Journal of Economics

p-ISSN: 2166-4951 e-ISSN: 2166-496X

2013; 3(C): 41-46

doi:10.5923/c.economics.201301.08

Logistic of Palm Oil Industry in Agri Supply Chain Using Simulation Software: State of the Art and Research Directions

F. Lestari1, K. Ismail2, A. B. Abdul Hamid2, W. Sutopo3

1PhD Student on Faculty of Management And Human Resource Development, Universiti Teknologi Malaysia, Malaysia

2Faculty of Management And Human Resource Development, Universiti Teknologi Malaysia, Malaysia

3Department of Industrial Engineering, Sebelas Maret University, Indonesia

Correspondence to: K. Ismail, Faculty of Management And Human Resource Development, Universiti Teknologi Malaysia, Malaysia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Supply chain in agriculture has the high complexity on logistic system. According on scope of this paper, business processes on palm oil industry include flow of Fruit Fresh Bunch (FFB) from plantation to the customer as derivative product of palm oil. There are several flows that linkage among entities within logistic system involving plantation, processing industry, storage, Industry of palm oil derivative product and market. This paper presents state of the art of improvement on performance measurement which identifies its indicator using simulation software. Finding on this review will be developed into research directions for further research. It is necessary to note that simulation software can simplify business process and improve the performance indicator in the logistic system.

Keywords: Agri Supply Chain, Logistic, Palm Oil, Simulation, Performance

Cite this paper: F. Lestari, K. Ismail, A. B. Abdul Hamid, W. Sutopo, Logistic of Palm Oil Industry in Agri Supply Chain Using Simulation Software: State of the Art and Research Directions, American Journal of Economics, Vol. 3 No. C, 2013, pp. 41-46. doi: 10.5923/c.economics.201301.08.

Article Outline

1. Introduction

- Success of Supply Chain in Agriculture (ASC) is affected by food quality, food safety, and weather related variability. Therefore, ASC products which are perishable faced problems of short product lifetime making it even more complex. The entire of agriculture processes are began at harvesting in plantation, processed industry, storage and distribute to customer. In this paper, present case study on supply chain management in palm oil industry. Fruit from plantation of palm oil has characteristics as perishable product and uncertainty. According to van donk et al.,[1] uncertainties and complex operational characteristics increase the need for integration. Therefore, the constructs of ASC practices in palm oil industry will emphasize on integration. To achieve customer requirement on palm oil derivative products, palm oil industry not only focus on quality of product but also manage logistic strategy to offer a product with better service and lower cost.Developing of facilities on logistic system from upstream to downstream is done to support supply chain in palm oil Industry. Nowadays, one of player in palm oil industry like Malaysia has infrastructure on logistic strategy had been established to run their business. For the year 2012 only, palm oil industries contribute total export earnings of RM 52,95 billion[2]. Nevertheless, the research have founded production cost of palm oil achieve 70% on period 1997-2008[3]. Thus, the profit is still not optimum. The paper will review how palm oil industries increase its productivity with managing logistic system to reduce production cost. Optimization on logistic system was done with deciding performance indicator within the business which the principles of the scorecard were used to identify performance indicator. Based on this case, the indicators were used as a tool to reorganize the supply chain and measured to decide ability in existing logistic system[4]. In addition, improvements are done with increasing certain value in indicator. Indeed, maximization of profit and improving competitiveness are the main purposes of driving supply chain.Design on the indicators aims to propose an approach for developing a scorecard based on simulation modeling. Simulation is used to study and optimize the system behavior while acting on the indicator values. According Beshara et al.,[5] their research improves a set of performance measurement by developing a simulation model that helps in evaluating and analyzing the performance of these supply chains. Simulation modeling builds a conceptual model which representative with the real system so improvement of the system can be done without spending a lot of cost for the implementation of unsuccessfully programs[6].Finally, simulation modeling on supply chain agriculture can be used in the palm oil industry because it can directly view the flow of material and information on each process so bottlenecks are seen clearly. Furthermore, this tools can solve the problem on a system with high complexity, interdependence (discrete event simulation)[7], and can solve stochastic cases[8]. Methodology in the review is done by gathering some research using simulation modeling in supply chain of agricultural in sector of plantation, industrial process, and distribute to the market. These brief reviews consider only journal paper and other references published in the period 2005 to 2012. Furthermore, this review is expected to be able to contribute in measuring performance logistics system oil industry from upstream to downstream.

2. Logistic And Supply Chain

- Strategy logistics and Supply Chain Management (SCM) is one of the strategies used to win the market. This strategy aims to minimize production costs with minimal resources to achieve more profit and customer satisfaction at the right time in the right place and the right amount.

2.1. Definition

- Logistic is a set of resource raw material, product, equipment and human from production line to customer[9]. In other hand, SCM is integration and management of organization and activities through cooperative organization relationship, effective business process, and high levels of information sharing to create high-performing value systems that provide member organizations a sustainable competitive advantage[10]. Thus, relationship logistic and SCM is exchanging of material flows, and financial information. This exchange occurs from upstream to downstream by providing some benefit to the product. Application on logistic and SCM cover with production and large geographic-scale distribution of a diversified set of goods. They are like horticultural, meat, fishery, dairy, bakery, beverages and other products are proposing logistic and safety challenges which require an implementation of the technology[11].However, researcher found these strategies used on different constructs for different country. In fact, the managerial has different of perceptions and cultures on how to arrange strategy on its organization[12]. Previous studies have shown that different industry may also have a different effect on SCM practices ([13],[14]). To solve these problems, decision maker should find fitting on SCM approach and model based on respective business activities and processes.There are several barriers to implement strategy on SCM. Relationship between the members of a supply chain becomes one of the important barriers in achieving the supply chain integration. Furthermore, it is important to see the integration aspects between the members of the supply chain[15].

2.2. Method and Tools

- Logistic and SCM in achieving the goal are supported by tools and method. The analytical tools used to measure or to calculate the performance indicator can be divided: analytical[16] and simulation[17]. Most of the reviewed papers used analytical approaches, followed by the use of simulation models. The solution technique refers to the way of solving the problem, in other words how to find the results. Each tool has strength and weakness depends on the case which will is solved. The cases which describe of flow material from upstream to downstream are suggested to uses simulation analytical rather than others approach. Therefore, it shows several scenarios to improve the system and also to help in studying real life situations needed.

3. Using Simulation in Agriculture

- The Agriculture is a complex system that operates a large number of players. The objective of supply chain in agriculture practice was imposed under the pressure of having to best meet the customer at lower cost. In this context, the question arises is how to predict the existing situation to improve it. Simulation modeling is the best way to solve those problems[18].

3.1. Simulation

- Simulation is one of the most widely used operation research and management science technique. This approach can predict the performance of a process without having to go through actual implementation. In addition, one of implementation simulation using software which can reduce the time to develop model encourage more the utilization of this technique in process improvement[19]. Several Researches using simulation modeling have been done to solve the problem within system. Chan and Chan[20] focused on the use of simulation in predicting different system designs of new printed circuit board (PCB) manufacturing system. They found that simulation model can easily be modified for the use of PCB manufacturing plant. Barragan et al.,[21] studied simulation and optimization of gas and oil production. They proposed an innovative model, which represented by a set of difficult differential equations. Result that shows from simulation modeling should be validated in order to objective on the model suitable with the actual system. According J. Banks et al.,[22] validation is concerned with building the model correctly and verification concerned with building the correct model. In addition, developed and validated a measurement instrument for studying supply chain management practices.

3.2. Review Simulation Software

- There are several simulation software used to solve problem on supply chain management such as WITNESS, SCOR and ARENA. Noor ajian et al.,[8] they have researched; as the result, Simulation model replicating the existing Fruit Fresh Bunch (FFB) department system was developed using the WITNESS simulation software. Parsson and Araldi,[23] in their research describe the SCOR model has been used in order to simulate the supply chain. This framework is build simulation models that integrate discrete event simulation tool and SCOR methodology. Furthermore, There is paper presents a methodology to simulate the vehicle scheduling in flight logistic support process and optimizes the vehicle support process by using the discrete event simulation software Arena[24].

3.3. Measurement of Key Performance Indicator

- Performance measurement system (PMS) is critical to the success of the supply chain and to gain competitive advantages and continuously react and adapt to external changes[25]. The key issue for improvement is measuring the performance of the activities, the processes, and the supply chain. The Key Performances Indicators (KPI) of perspective on logistical driver are facility, inventory and transportation and cross functional drivers are information, sourcing and pricing. The supply chain council on SCOR model[26] emphasize there are four measurements in supply chain management: reliability measures, cost measures, responsiveness measure, and asset measurement.

4. Application on Logistic Palm Oil

- This paper tries to provide an alternative solution to improve the performance of the system in the field of agriculture. One application is taken to measure the performance of the logistic review is the case of palm oil industry supply chain. The palm oil business is an industry that has a complex business chain. Business processes are initiated from plantation, and then processed by the processing industries, distributed to industry of product developers who produce diverse product until the end user as customer. These industries consist of many businesses along the supply-chain, which can be divided into four sub-sectors: growers, millers, refiners, and oleochemicals[27].

4.1. Plantation

- Fruit from the plantation in form of fruit fresh bunch (FFB) is harvested and will be sent to the processing industries. The fresh product has short product lifetime thus making it more complex. As the result, the FFB are not allowed to be stored for long time thus FFB can be categorized for perishable products. According Beshara et al., Perish-ability refers to physical deterioration of a product which represents a huge challenge on the performance of supply chain.

4.2. Processing Industry

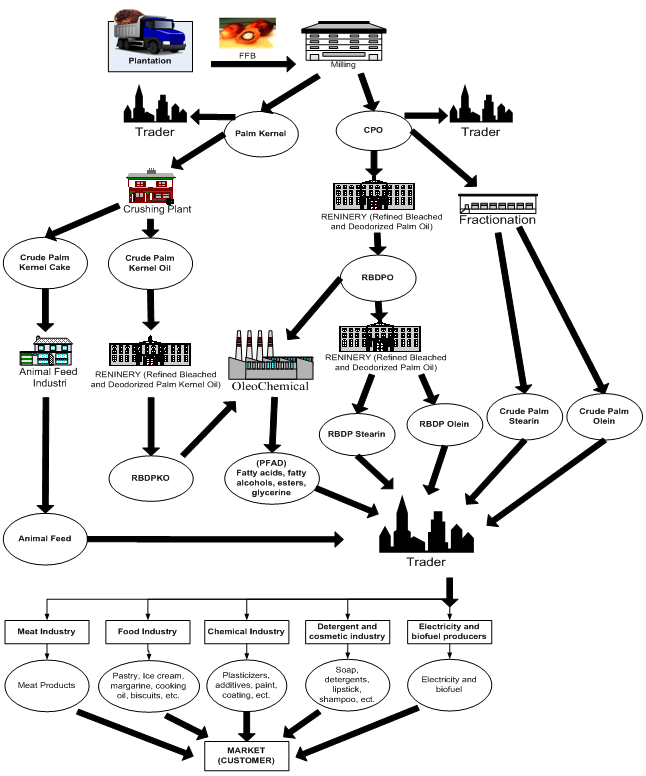

- The yield of palm oil plantations in form Fruit Fresh Bunch (FFB) will be taken to the processing industries. FFB will be processed in industry milling to produce palm oil such as Crude Palm Oil (CPO) and Palm Kernel. Furthermore, Palm Kernel is processed by crushing industry to produce Crude Palm Kernel Oil (CPKO) and other byproducts such as Palm Kernel Cake can be directly sold to be used as animal feed. Then, CPKO and CPO are processed in the refining industry. Not all CPO was produced by refineries, but partly through the fractionation processes that produce Crude Palm Olein and Crude Palm Stearin. The process of refinery including Refined Bleached and Deodorized Palm Oil produces (RBDPO) products. Then, it done distillery to be RBDP Stearin and RBDP Olein. On the other hand, RBDPO products through the Oleochemical process to produce Palm Fatty Acid Destilate (PFAD).

4.3. Distribution

- Product palm oil derivative that has been produced will be traded to the local and international market. Export and import of products derived palm oil companies’ use shipping services. Thus, there are some companies that used the port distribution center for export of palm oil derivative to the market internationally. In addition, trading of palm oil is not only targeting the international market. To help grow the local industry, partly palm oil derivative traded in the local market. Even some companies in the industry to import palm oil products derived from outside the country.

4.4. Market

- The international market is more dominant than the targeted local market like Malaysia and Indonesia. The biggest earn for CPO and PKO products. These oils will be processed by the developed countries to retail businesses such as food products, chemical industry, personal care products, animal feed, cleaning products and several source of energy.Based on four entities in supply chain palm oil industry, there are linked among stakeholders to run the business. Simulation software is used to measure the performance and to improve the system. Figure 1 describe conceptual model on agri supply chain in palm oil logistic. According this illustration, it shows there are several flows such as physical flow, information and returning in relationship among entities. The processes have interdependency as discrete event simulation can be implemented. In addition, the system present stochastic approach to face possibility problem in distribution flows.

| Figure 1. Conceptual logistic model on supply chain in palm oil industry |

5. Research Directions

- The scope of this research is began from harvesting FFB in plantation and then distribute to the customer as product derivative of palm oil. FFB in plantation will be distributed to the processing industry which is discrete (or batching) process. Then, FFB is processed on refinery which it is in continuous process. The last, scenario of transportation facility is a stochastic approach. Such uniqueness requires special consideration. Therefore, this critical point will be researched using simulation software in order to improve the performance indicator. In fulfilling the objective, the following questions should be addressed:1. What the current entity and how their relationship on agri supply chain in logistic system of palm oil? 2. How to develop conceptual model that will be measure the performance system using simulation software?3. What type of key performance indicator on logistic strategy in palm oil industry? 4. What the best logistic method that will be implemented on case study on palm oil industry?5. How about result of performance indicator after improving is done?Through this review paper, the further research proposes an approach to design performance indicator and measure the performance logistic system in palm oil using simulation software.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML